Vilnius, T. Žebrausko g. 7

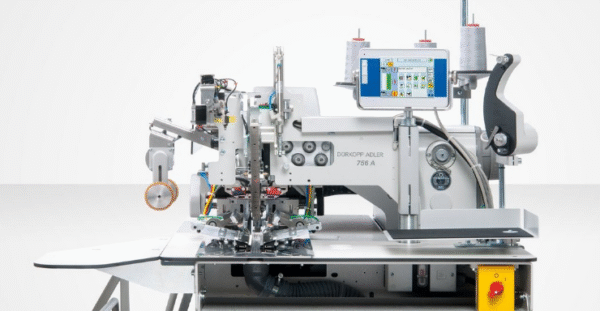

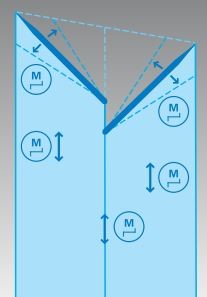

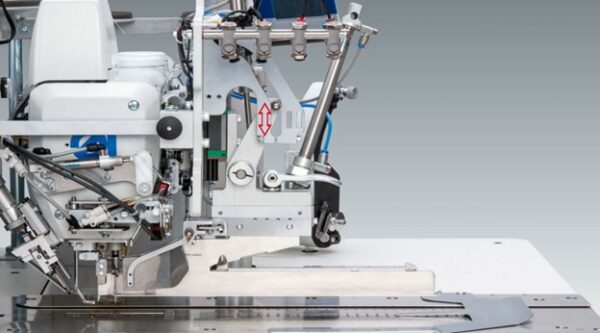

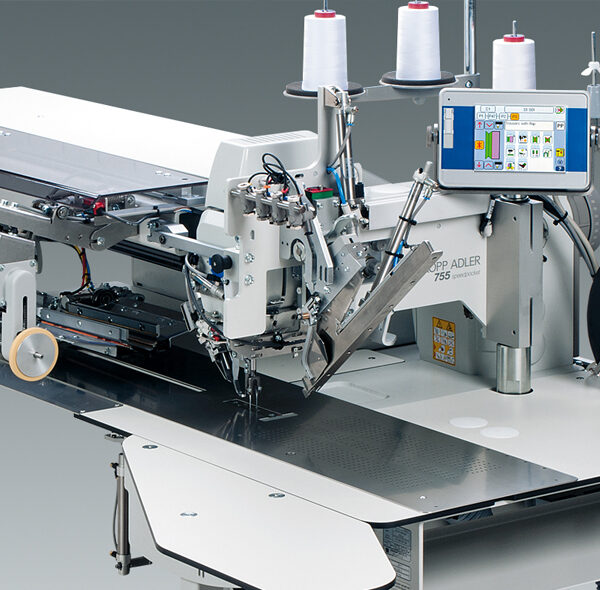

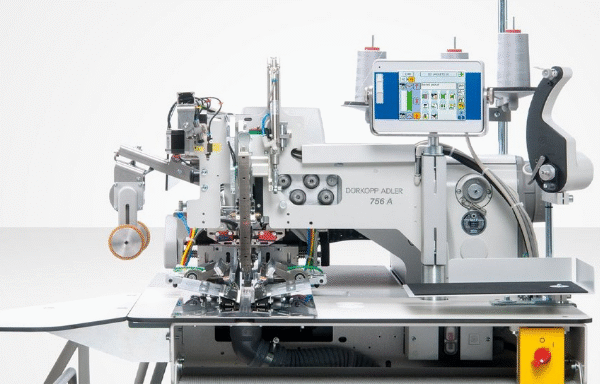

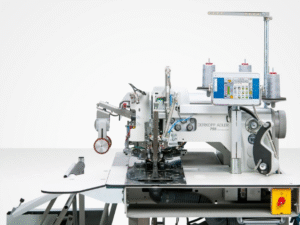

Duerkopp Adler 755 A / 756 A – Sewing units for runstitching of straight and slanted piped pockets, flap pockets and welt pockets

755 A / 756 A: High-Performance Sewing Units for a Variety of Pocket Styles

Efficient, Flexible, and Powerful – The Key to Pocket Production

The 755A and 756A sewing units are designed to revolutionize your pocket-making process. These machines excel at producing precise and consistent runstitches for a wide range of pocket styles, including:

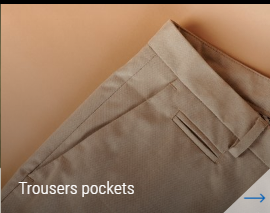

- Straight and slanted piped pockets

- Flap pockets

- Welt pockets

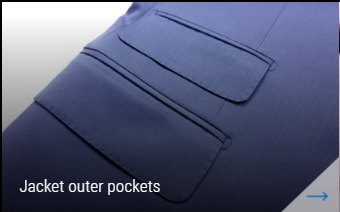

Whether you’re working with rectangular pockets, frequently changing pocket lengths, or alternating between breast welt pockets and jacket outer pockets, these units adapt seamlessly. The user-friendly touch control panel allows for effortless adjustments, making transitions between different pocket styles quick and easy. Plus, the manual feeding of facing parts, combined with optional add-ons, boosts both productivity and flexibility on your production floor.

Key Features & Benefits:

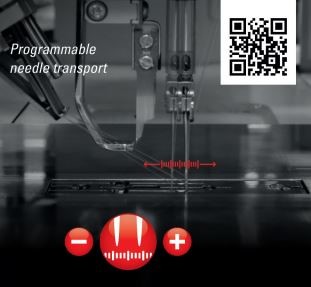

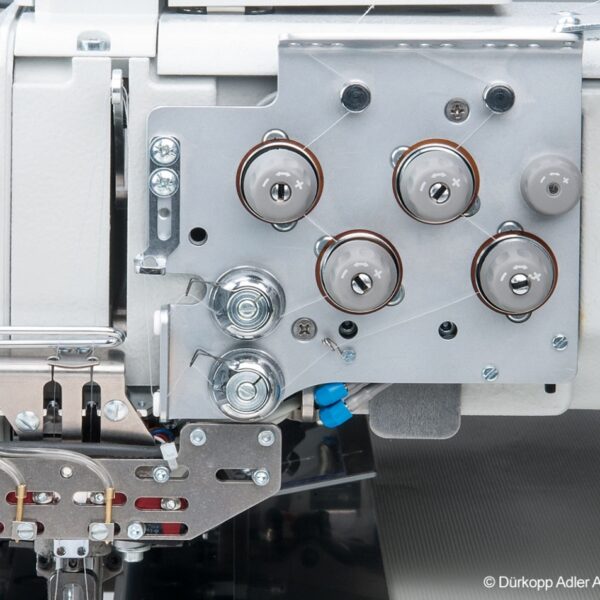

- Precision Stitching: Features needle feed and stepper motor-controlled transport clamp adjustment to ensure accurate and consistent stitch placement.

- Laser Guidance: Equipped with laser marking lamps for precise material alignment.

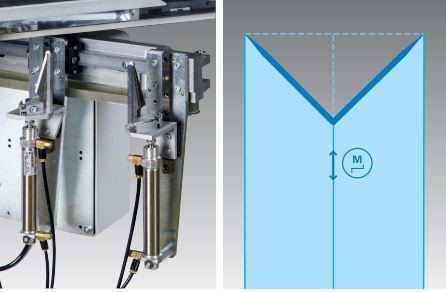

- Center Blade Drive: Provides clean and reliable cutting for consistent pocket openings.

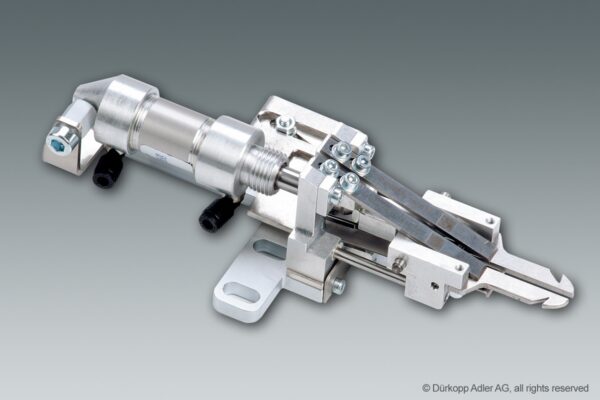

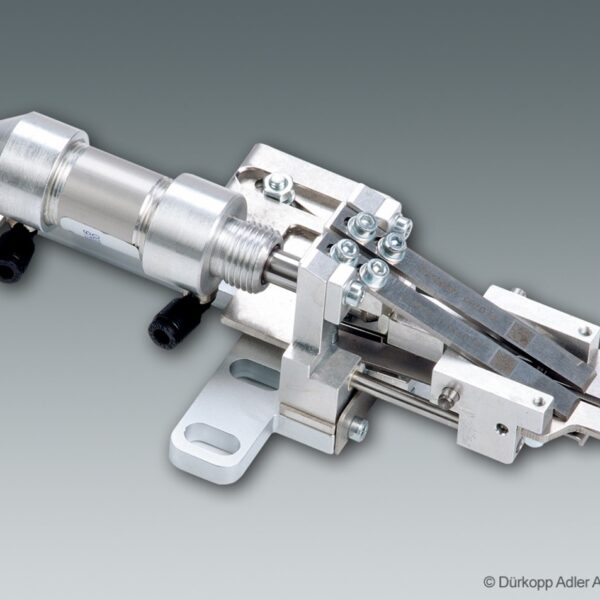

- Advanced Knife Stations:

- 756 A: Includes a multifunction corner knife station designed for both straight and slanted pockets.

- 755 A: Features an optional automatic corner knife station, also for straight pockets.

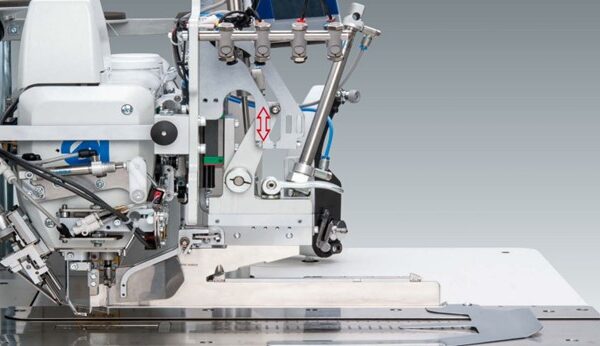

- Optimized Folder System: The improved folder lowering ensures smooth and consistent material handling.

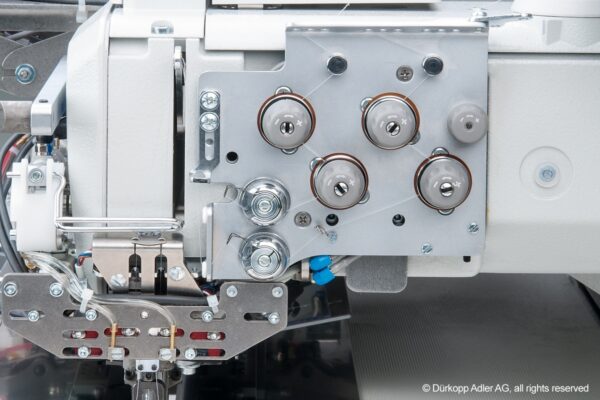

- Customizable Tension: Includes an additional thread tension system for ideal stitch quality.

- Integrated Cutting: An efficient cutting device for precise pocket trimming.

- Automated Stacking: Features a flip stacker to streamline the post-sewing process.

- Adjustable Transport: Offers customizable transport clamp pressure for different fabrics.

- Innovative Folder Design: A new folder concept enhances the sewing unit’s adaptability and performance.

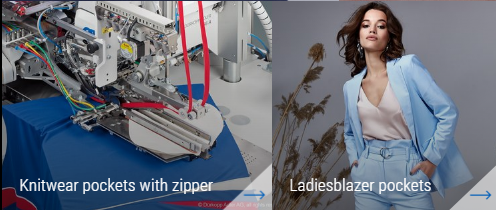

Versatile Applications:

These sewing units are ideal for a wide array of applications, including:

- Producing high-quality pockets in various garments.

- Manufacturing both interior and exterior pockets, including breast and jacket pockets.

- Handling a variety of pocket styles with ease and efficiency.

Technical Specifications at a Glance:

|

Feature |

755 A |

756 A |

|

Stitch Length |

0.5 – 4.5 mm |

0.5 – 4.5 mm |

|

Maximum Speed |

3,200 stitches/min |

3,000 stitches/min |

|

Suitable Materials |

Light, Medium, & Heavy Fabrics |

Light, Medium, & Heavy Fabrics |

|

Seam Length |

20 – 240 mm * |

20 – 240 mm * |

|

Twin Needle Capability |

4.8 – 30 mm * |

4.8 – 30 mm * |

|

Stitch Type |

Lockstitch (301) |

Lockstitch (301) |

|

Hook System |

Vertical, Large (Ø 26 mm) |

Vertical, Large (Ø 26 mm) |

|

Key Features |

* Programmable needle transport, Clamp adjustment with material spreading, Automatic thread trimmer, Automatic corner knife station (straight pockets), Automatic stitch condensing, Needle and bobbin thread monitors, Reflective light barriers for start/stop, Suction device, Flip stacker, Bundle clamp with rest table, Touchscreen control panel.* |

Programmable needle transport, Clamp adjustment with material spreading, Automatic thread trimmer, Multifunction corner knife station (straight & slanted pockets), Automatic stitch condensing, Needle and bobbin thread monitors, Reflective light barriers for start/stop, Suction device, Flip stacker, Bundle clamp with rest table, Touchscreen control panel. |

- Dimensions dependent on configuration

Advanced Control and Automation:

Both models feature the OP7000 operating panel with a clear graphic display and touchscreen interface, providing intuitive control over all sewing parameters. Additional automated features include:

- Automatic stitch condensing

- Needle and bobbin thread monitoring

- Reflective light barriers for automatic sewing start and stop

- A suction device for precise fabric positioning.

Elevate Your Pocket Production:

The 755A and 756A sewing units offer a powerful combination of speed, precision, and versatility, making them an essential investment for any garment manufacturer looking to optimize their pocket production process.

| Stitch type | Lockstich |

|---|---|

| PLATFORM TYPE | Flat bed |

| Segment of production | Garment |

| Manufacturer | |

| Type of hook | Vertical |

Reviews

There are no reviews yet.