Vilnius, T. Žebrausko g. 7

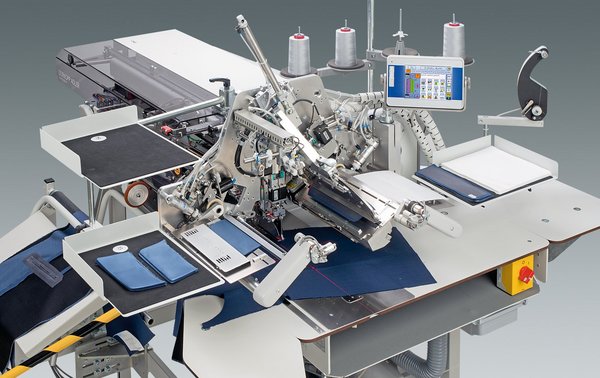

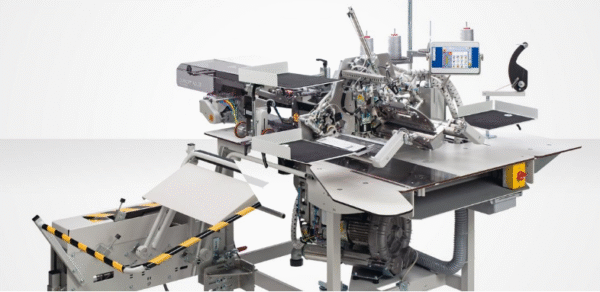

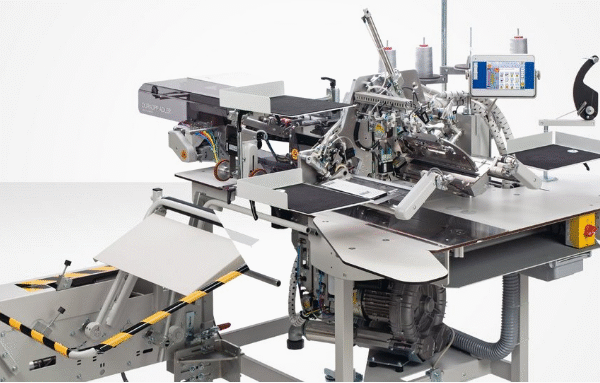

Durkopp Adler 756 F – Sewing unit for runstitching straight and slanted pocket openings with fully automatic feeding device and pattern matching

756 F | Sewing unit for runstitching straight and slanted pocket openings with fully automatic feeding device and pattern matching

Up to 20% time safe in the pocket manufacturing

Are you looking for a comfortable solution for your jacket pocket production? The most comfortable solution is the 756 F. With its automatic feeding, pattern matching and cutting device, it fulfills the desire for perfect quality in use for outside and inside pockets. Whether in patterned or unpatterned fabric, the sewing unit achieves in the simplest way a pattern matching at the highest level. The need to mark the pocket position is eliminated by the matching device, thus reducing the cycle time of the operation.

Fully automatic feeding methods

With these feeding methods, the piping strips, flaps and pocket bags are fed fully automatically. This method allows a fully over lapped operation when loading the sewing unit. While the sewing unit sews the pocket, the piping ends can already be cut and the pocket components of the following pocket can be loaded and positioned exactly.

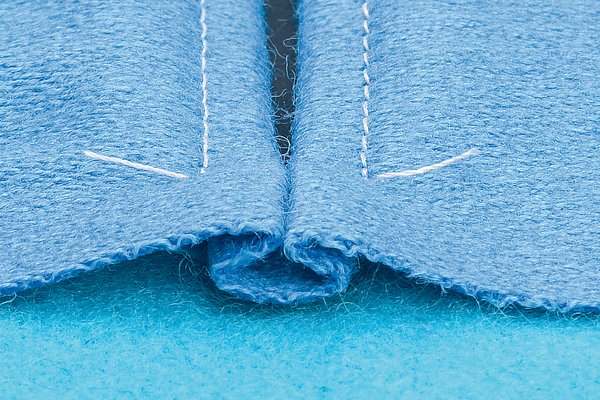

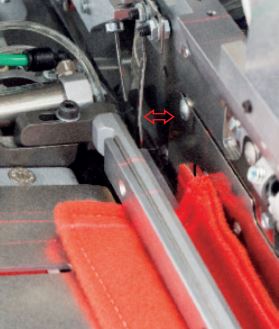

Quality improvement and increase in productivity due to the fully automatic piping end cutting

The cutting of the piping ends significantly increases your pocket quality. Marks and shiny spots caused by ironing are visibly reduced with less material layers. In connection with striped fabric, an absolutely exact, pattern correct application of the piping strips is possible. The fully automatic cutting of the piping ends during the sewing process means a time saving of approx. 20% compared to conventional manual cutting with the scissors.

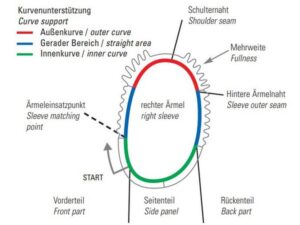

Saving of markings for checkered and striped fabrics

Save marking your pocket openings with the fully automatic feeding and matching device. The matching device allows the flaps on the front part to be matched directly in accordance with the pattern, without additional marking of the flap position.

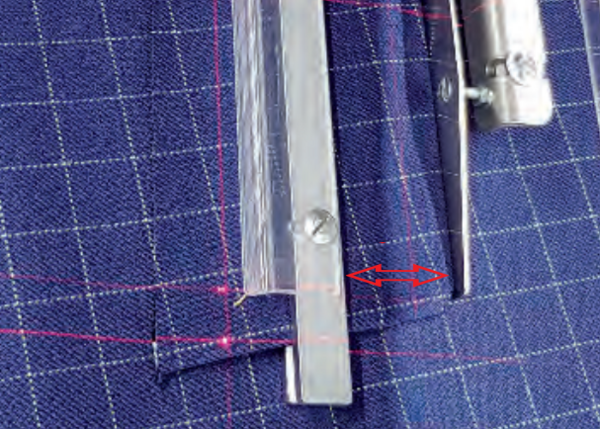

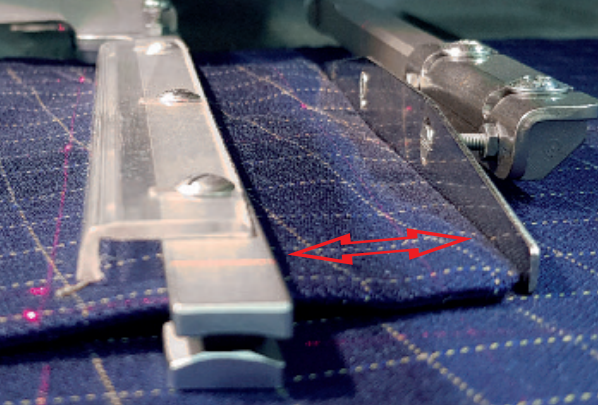

Adjustable flap guide

To counteract the inaccuracy when using flaps with the help of laser marking lights, the 756 F offers a mechanically adjustable flap guide.This allows the constant flap width to be adjusted and pocket quality to be ensured. The flap guide, which is mechanically adjustable via a knurled nut, allows perfect flap width when matching to pattern material.

Unique programmable material adjustment

For easy setting of different material thicknesses by the operator – pocket materials of different thickness can be processed one after the other without mechanical adjustments. The programming for the height of the folding guide plates and the folder height, allow a perfect adaptation to different material thicknesses with only one touch.

Enlarged material passage

The perfected folder system with improved material passage enables the simple and quick exchange of folder and sole inserts in a few minutes.

Programmable flap pattern correction

The programmable flap pattern correction in cross direction, increases the flexibility in the use of different fabric thickness with pattern matching. Mechanical adjustment to different materials is therefore no longer necessary and can be programmed by the operator.

Examples of use

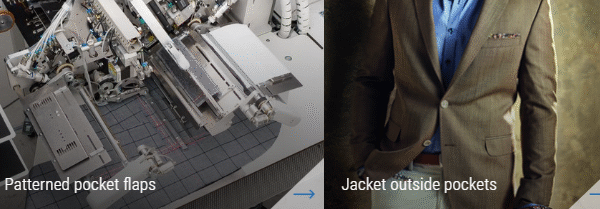

Pattern pocket flaps

Performance in 480 min.

Slanted Single-/double piped pockets with flaps in jackets (patterned).

Additional parts: Flap, piping strip, pocket bag (attached); approx. 1,000 – 1,200 pockets.

Jackets outside pockets

Slanted single-/double piped pockets with flaps in jackets (unicoloured).

Additional parts: Flap, piping strip, pocket bag (positioned underneath or attached); approx. 1,600 – 2,000 pockets in 480.

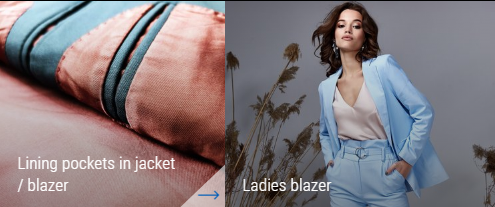

Lining pockets in jackets/blazers

Single-/double piped pockets in lining.

Additional parts: piping strip, 2 pocket bags, lining flap triangle; approx. 1,400 – 1,600 / 480.

Ladies blazers

Table of Specifications – Sewing Machine 756 F

| Feature | Details |

|---|---|

| Machine Model | 756 F |

| Stitch Length | 0.5 – 4.5 mm |

| Standard Stitch Length | 3.000 mm |

| Sewing Material | LM / M / MS |

| Max. Seam Length | 20 cm |

| Max. Twin Needle Distance | 10 cm |

| Twin Needle Feature | Disengageable |

| Stitch Type | Lockstitch (301) |

| Hook Type | Vertical hook, large (L, Ø 26 mm) |

| Needle Transport | Programmable |

| Clamp Adjustment | with material spreading |

| Thread Trimmer | Automatic |

| Center Knife | with counter knife, separately motor driven |

| Piping Strip Feed | Automatic |

| Flaps & Parts Feed | Automatic |

| Matching Device | Automatic |

| Stitch Condensing | Automatic |

| Needle Thread Monitor | Yes |

| Bobbin Thread Monitor | Yes |

| Bobbin Thread Control | Yes |

| Suction Device | For exact fabric positioning |

| Program Control | Operating panel OP7000 with graphic display and touch screen |

Technical Specifications

| Feature | Details |

|---|---|

| Machine Model | 756 F |

| Air Requirement/Stroke | 6 liters |

| Air Pressure | 6 bar |

| Needle System | 134-35/DPX and others |

| Needle Size | 80-110 |

| Nominal Voltage | 1x230V, 50/60 Hz |

| Rated Power | 500 Watts |

| Weight, Sewing Head | 220 kg |

| Weight, Complete | 320 kg |

| Packaging Size (L/W/H) | 1830 mm / 1230 mm / 1590 mm |

| Stitch type | Lockstich |

|---|---|

| PLATFORM TYPE | Flat bed |

| Segment of production | Garment |

| Manufacturer | |

| Type of hook | Vertical |

Reviews

There are no reviews yet.