Vilnius, T. Žebrausko g. 7

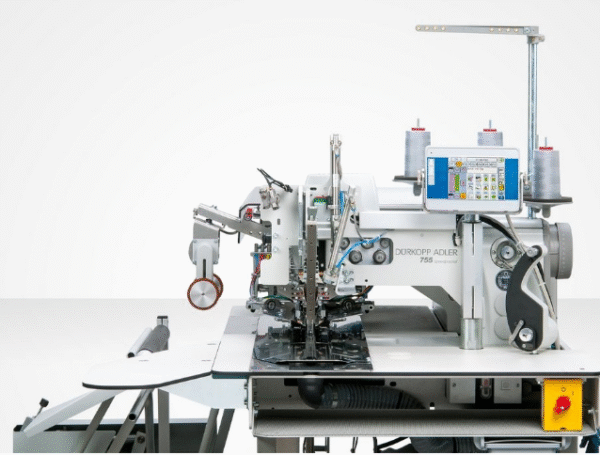

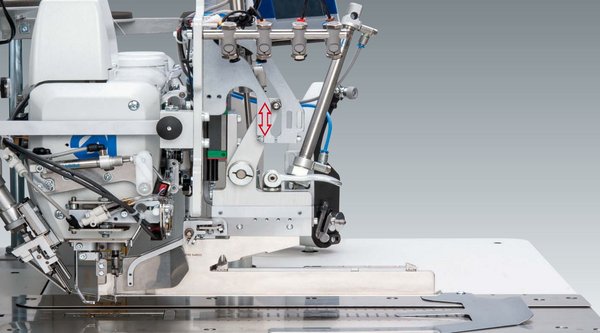

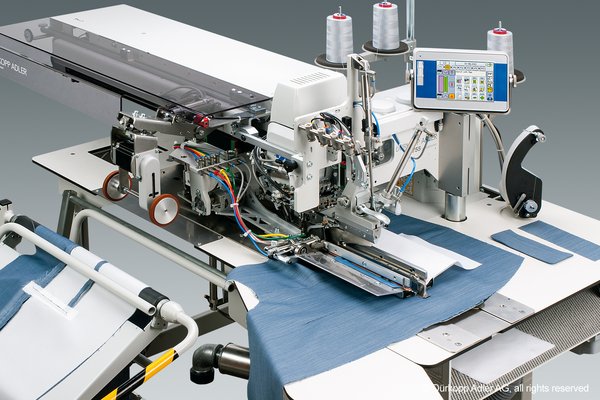

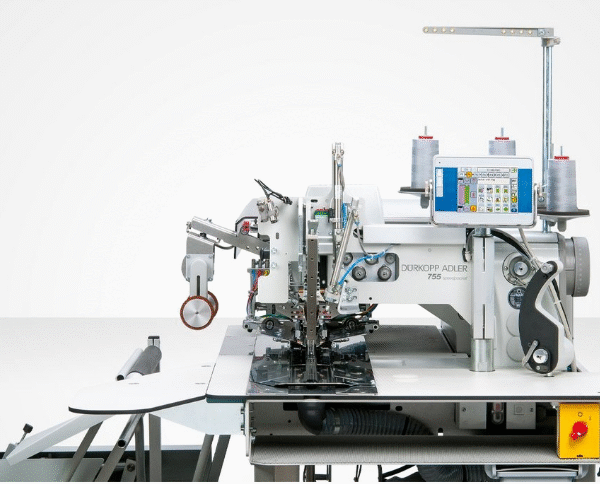

Duerkopp Adler 755S – Sewing unit for runstitching of rectangular piped pockets, flap pockets and welt pockets

755S | Sewing unit for runstitching of rectangular piped pockets, flap pockets and welt pockets

Innovative and powerful piping technology

The efficient piped pocket sewing unit 755-S is a must for any standardized production of rectangular piped pockets, flap and welt pockets. The manual feeding of the additional parts in conjunction with optional additional equipment increases the performance of your production and increases the flexibility of the sewing unit.

Your benefits at a glance

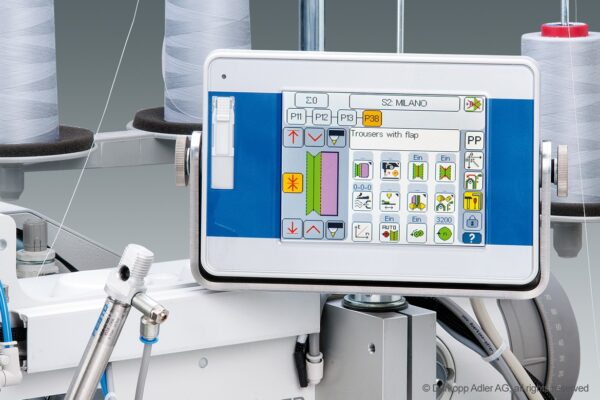

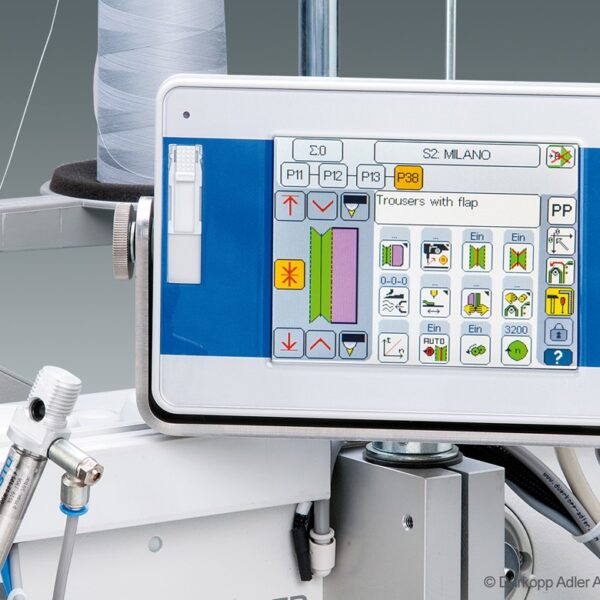

· High-quality control system with DAC comfort. Machine parameters can be copied via USB flash drive; Saving of machine parameters in machine-ID.

· Technical highlight – Touch-Screen OP7000 with colour graphic display. Free programmable pocket parameters; max. 99 seam programs; 8 standard programs for different applications; max. 20 sequences with up to 8 seam programs; freely designable user interface for functions.

Language selection: The 755 offers as standard a language selection of 15 languages: D, GB, E, F, P, I, TR, CN, VN, RU, HI, BN, RU, BG and RO.

· Needle distances from 6 – 30 mm can be selected, short conversion time from one to the other needle distance (approx. 30 min.)

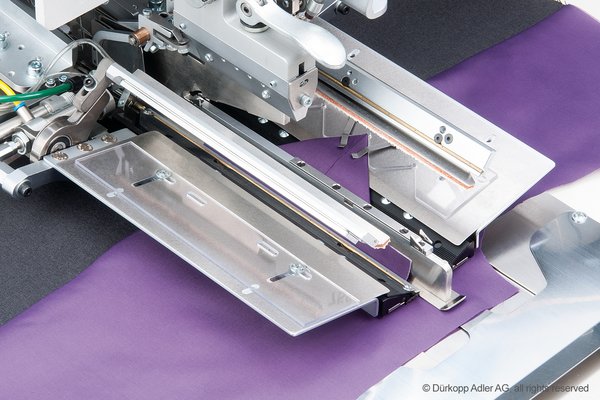

· Stepper motor driven center blade drive with extended flexibility in material use due to increased material flow. Stepper motor-controlled middle blade drive with increased flexibility in material use due to increased material passage and adjustable stroke for adaptation to the material thickness – reduced knife wear.

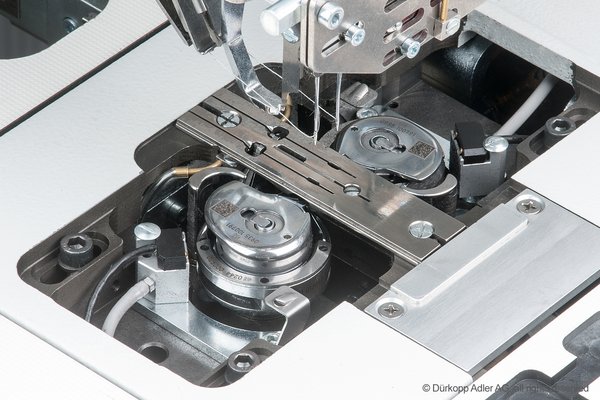

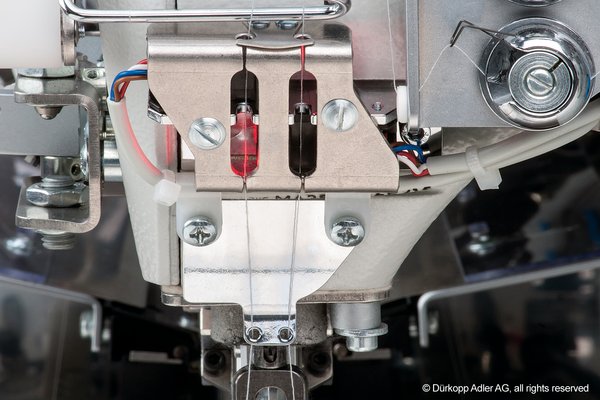

· Reduced bobbin change due to double bobbin volume with large vertical hook (Ø = 26 mm). Large three-piece hook with capsule fan (Ø 26 mm) allows a reduced bobbin change due to double bobbin volume. A small vertical hook (0755 150064 / Ø = 22 mm) is available as an option.

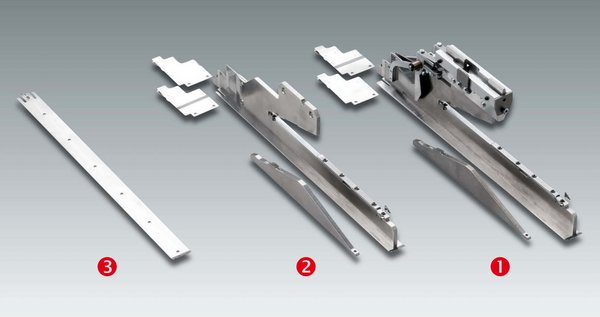

· New folder concept as modular system . The complete folder (1) consists of a folder ins ert (2) with sole (3). In order to reduce the costs of changing the folders, it is possible to change the folder ins ert or the sole only.

· Optimized folder lowering – for tension free folder movement onto the material

· The folder lowering is optimized by its horizontal movements before reaching the transport clamp. This improves the folding process of the piping strip and prevents the material from slipping during the folding process.

· Quick-release fastener for changing the folders without tools

· Quick-change connector (option) for quick replacement of heads with frequent needle distance changes

· Maximum precision in the corner cuts due to easy-to adjust corner knife station option. Corner knife system (Option 755 337534). Maximum precision of straight corner incisions due to easily adjustable corner knife system, can be swivelled out for cleaning and maintenance.

· Processing of trousers pockets with extra wide piping strips up to 60 mm, with integrated blowing device (option) Over-wide piping strips. Optimized folder for over-wide piping strips for trousers pockets with extra wide piping strips up to 60 mm on the left. The integrated blowing device (option) serves to raise the extra wide piping strips. K35-LR180 – Part se t 0755 590804 K35-LR220 – Part se t 0755 590814.

· Further advantages

– Save the machine parameters in the machine ID*

– Safe and clean winding of the thread when spooling with integrated bobbin winder with winding aid

– Fast color changing possible by separately driven bobbin winder (option) – Large arm passage (335 mm) on the right hand side of the needle

– High sewing safety thanks to needle thread and bobbin thread monitor in the standard of the sewing unit

– Flap scanning via photocell

– Pocket sizes from 20 – 240 mm selectable (depending on sewing equipment)

– Pressure monitor is included as standard

– UPS – uninterrupted power supply (option)

Examples of use

· Double piped pockets in back trousers

Accessories: Piping strips, pocket bags (underlaid); approx. 2,200 – 2,600 pockets in 480 min.

· Single piped pockets in hind trousers

Additional parts: piping strip, pocket bag (positioned underneath) approx. 2,200 – 2,600 pockets in 480 min.

· Single- or double piped pockets withflap in hind trousers

Additional parts: flap, piping strip, pocket bag (positioned underneath); approx. 1,500 – 1,800 pockets in 480 min.

· Single- or double piped pockets withflap in hind trousers

Additional parts: flap, piping strip, pocket bag (positioned underneath); approx. 1,500 – 1,800 pockets in 480 min.

· Lining inside pockets

Additional parts: piping strip, 2 pocket bags; with lining flap triangle: approx. 1,200 – 1,400 pockets in 480 min.; without lining flap triangle: approx. 1,400 – 1,600 pockets in 480 min.

Technical Specifications:

|

Feature |

Technical Details |

Standard / Optional |

|

Stitch Details |

||

|

Stitch length |

0.5 – 4.5 mm |

Standard |

|

Stitches/min. |

3,200 |

Standard |

|

Sewing Material |

LM / M / MS |

Standard |

|

Seam length |

20 – 240 mm (depending on sewing equipment) |

Standard |

|

Twin needle spacing |

6 – 30 mm (other by request) |

Standard |

|

Stitch Type & Hooks |

||

|

Lockstitch |

(301) |

Standard |

|

Horizontal hook |

Large (L, Ø 26 mm) |

Standard |

|

Horizontal hook |

Small (S, Ø 22mm) |

Optional |

|

Automated Functions |

||

|

Thread trimmer |

Automatic |

Standard |

|

Corner incision device |

Straight |

Optional |

|

Centre knife with counter knife |

Separately motor driven |

Standard |

|

Stitch condensing |

Automatic |

Standard |

|

Monitoring Systems |

||

|

Needle thread monitor |

Included |

Standard |

|

Bobbin thread monitor |

Included |

Standard |

|

Bobbin thread control |

Included |

Standard |

|

Sensing & Positioning |

||

|

Reflecting light barrier |

Automatic sewing start at fabric beginning |

Standard |

|

Reflecting light barrier |

Automatic sewing stop at fabric end |

Standard |

|

Suction device for positioning |

For exact fabric positioning |

Optional |

|

Fabric Handling |

||

|

Bundle clamp with rest table |

Optional |

|

|

Control & Interface |

||

|

Program control |

Operating panel OP7000 with graphic display and touch screen |

Standard |

|

Pneumatic Requirements |

||

|

Air requirement per stroke |

6 |

Standard |

|

Air pressure |

6 bar |

Standard |

|

Needle Specifications |

||

|

Needle system |

134-35/DPX |

Standard |

|

Needle size |

80-110 |

Standard |

|

Electrical Specifications |

||

|

Nominal voltage |

1x230V, 50/60 Hz |

Standard |

|

Rated power |

500 W |

Standard |

|

Weight & Dimensions |

||

|

Weight, sewing head |

240 kg |

Standard |

|

Weight, complete |

340 kg |

Standard |

|

Packaging size (L/W/H) |

1830 mm / 1230 mm / 1590 mm |

Standard |

| Stitch type | Lockstich |

|---|---|

| PLATFORM TYPE | Flat bed |

| Segment of production | Garment |

| Manufacturer | |

| Type of hook | Vertical |

Reviews

There are no reviews yet.