Vilnius, T. Žebrausko g. 7

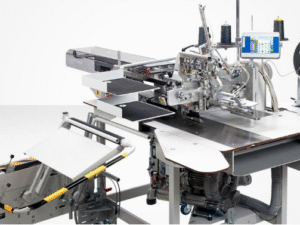

Durkopp Adler 630-10 – Optimized work station for pre-ruffling of sleeves

630-10 | Optimized work station for pre-ruffling of sleeves

Finest fullness nuances by means of differential top and bottom feed

Fullness where it is desired, perfectly symmetrical on the right and on the left, completely identical parts – no problem for the 630-10. The control panel allows quick and easy adaptation to different materials. All relevant data are clearly visible to the user.

Your benefits:

- Finest fullness nuances by means of differential top and bottom feed, individually selectable, stepper motor controlled, exact repetition even in difficult fabrics.

- Single programmable parameters

- Needle and bobbin thread tension, stitch length and speed can be programmed per step for a perfect stitch pattern independent of the material.

- Ergonomically designed work station

- Fatigue-free working with integrated LED sewing light and optimal view on the material.

- Short training times due to easiest operation

- “Teach-In” Easiest programming possible by “teach-in” procedure and automatic mirroring for the second sleeve. The touch screen with coloured graphic display of the seam course clearly shows the current program. All important parameters as e.g. fullness, thread tension, stitch length etc. are easily readable and programmable.

- Operating panel OP7000 The touch screen with coloured graphic display of the seam course clearly shows the current program.

- Programming in the size of your choice – standard grading values automatically calculate the program for every size

- Quick and easy software update and sewing program saving by USB flash drive

- Seam programming. The touch screen with coloured graphic display of the seam course clearly shows the current program.

- Constant fullness with exact repetition due to patented light stroke system

- Service-friendly calibration

Pre-ruffling of the sleeve crown, with sleeve head roll

A consistently high quality is achieved by the automatic program sequence, mirrored for right and left parts. Pre-ruffling of the sleeve crown, with or without sleeve head roll. In case of tailored workmanship the front sleeve seam is already closed.

Performance examples in 480 min.:

Pre-ruffling of approx. 450 – 500 pairs of closed sleeves

Pre-ruffling of approx. 550 pairs of open sleeves

Pre-ruffling of the sleeve crown, without sleeve head roll

A consistently high quality is achieved by the automatic program sequence, mirrored for right and left parts. Pre-ruffling of the sleeve crown, with or without sleeve head roll. In case of tailored workmanship the front sleeve seam is already closed.

Performance examples in 480 min.:

Pre-ruffling of approx. 450 – 500 pairs of closed sleeves

Pre-ruffling of approx. 550 pairs of open sleeves

Technical Specifications

|

Feature |

Technical Details |

|

Model |

630-10 |

|

Stitch Length |

1.0 – 4.0 mm |

|

Stitches per Minute |

5,000 |

|

Feeding Length |

8/6 mm |

|

Sewing Material |

L / M |

|

Needle System |

Single |

|

Stitch Type |

Double Chainstitch (401) |

|

Looper Type |

Crossline |

|

Feed Mechanism |

Differential Bottom Feed & Variable Top Feed |

|

Application |

Fullness Above, Flat Sewing, Fullness Below |

|

Thread Trimmer |

Yes, Pedal Controlled |

|

Other Features |

Stitch Condensing, Sewing Foot Lift, Program Control (OP7000 with Graphic Display and Touch Screen), Integrated LED Sewing Light with Dimmer |

|

Air Requirement per Stroke |

0.1 |

|

Air Pressure |

6 bar |

|

Needle System |

934 RG |

|

Needle Size |

70 – 130 |

|

Synthetic Thread Size |

120/3 – 70/3 |

|

Dimensions (L/W/H) |

1350 / 900 / 1100 mm |

|

Flat Bed Clearance |

281 / 144 mm |

|

Nominal Voltage |

1x230V, 50/60 Hz |

|

Power Consumption |

0.5 kW |

|

Weight (Sewing Head) |

54 kg |

|

Weight (Complete) |

108 kg |

| Stitch type | Chainstitch |

|---|---|

| PLATFORM TYPE | Flat bed |

| Segment of production | Garment |

| Manufacturer |

Reviews

There are no reviews yet.