Vilnius, T. Žebrausko g. 7

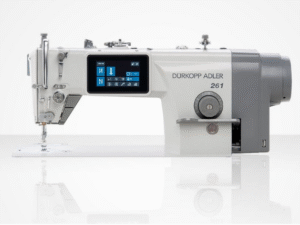

Durkopp Adler D887- e-con – Innovative and digitalized one or two needle flatbed sewing machines with wheel feed, needle feed and driven roller presser

The Dürkopp Adler D887-E-CON is an advanced industrial sewing machine designed for medium-heavy duty applications. It is part of the DELTA e-con platform, which focuses on digital, energy-efficient, and sustainable sewing solutions. This machine is notable for its sophisticated sewing kinematics and programmable settings that ensure precise and reproducible results, even with demanding materials.

Key features and benefits of the D887-E-CON include:

- Energy Efficiency: It offers 25% power savings compared to similar digital competitor machines.

- Digital Control: The machine uses a fully digital platform with intelligent control of power consumption, including the intelligent shut-off of motors and lights, and dimming of the control panel, to realize energy savings.

- Optimized Sewing Kinematics: Provides perfect and reproducible sewing results.

- Material Thickness Detection (MTD): Automatically optimizes sewing parameters during the sewing process.

- Intuitive Operation: Features a multi-touch control panel, reducing teach-in times by up to 30%.

- Program-Supported Sewing: Increases efficiency and reproducibility.

- Flexible and Future-Oriented: Designed with easy connection to Industry 4.0 and Poka Yoke applications, making it adaptable to advanced production systems.

- Versatile Application: Suitable for various applications including automotive seating, automotive interiors, leather goods, shoes, upholstery, and technical textiles.

- Safety Features: Includes Poka Yoke equipment to help avoid errors.

- Standard Package: Includes programmable height-adjustable work tables (optional).

- Advanced Features: Includes features such as a thread trimmer, bobbin thread monitor, skip stitch detection (SSD), and stepper motor-driven stitch length adjustment.

The D887-E-CON is designed to enhance productivity, reduce energy consumption, and improve the quality of sewing operations in medium-heavy material applications. It is a highly adaptable machine with various equipment and optional attachments to suit specific sewing needs.

Possible Subclasses

The D887-E-CON has a variety of subclasses that differ based on specific features.

- D887-143942-01: One needle, with a stitch length of 4mm Vertical hook, extra large (XXL, Ø 32 mm)

- D887-160922-01: One needle, with a stitch length of 7mm Vertical hook, large (XL, Ø 28 mm)

- D887-260922-01: Two needle, with a stitch length of 7mm Vertical hook, large (XL, Ø 28 mm)

- D887-353922-01: One needle, with a stitch length of 5mm Vertical hook, large (XL, Ø 28 mm)

These subclasses also feature different hook sizes, vertical or extra large, to handle a variety of threads and applications. All of the subclasses feature a wheel feed, needle feed and driven roller presser, along with a thread trimmer, bobbin thread monitor, and material thickness detection (MTD). The specific subclass will depend on the individual needs of the user.

|

Needle System |

134-35 |

|

Needle Size |

70-160 |

|

Synthetic |

120/3 – 10/3 |

|

Flat bed machine with clearance |

C=350 / D=128 |

|

Nominal Voltage |

1x230V, 50/60 Hz |

|

Rated Power |

375 |

| Stitch type | Lockstich |

|---|---|

| PLATFORM TYPE | Flat bed |

| Needle system | 134-35 |

| Segment of production | Automotive / Leather / Upholstery / Shoes |

| Manufacturer | |

| Type of hook | Vertical |

Reviews

There are no reviews yet.