Vilnius, T. Žebrausko g. 7

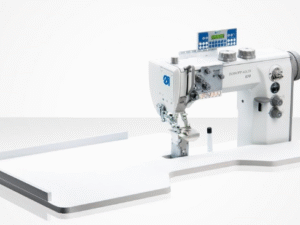

Durkopp Adler 806N – Sewing units for creasing and attaching pockets (knitted & woven fabrics)

806N | Sewing units for creasing and attaching pockets (knitted & woven fabrics)

Highest precision and quality

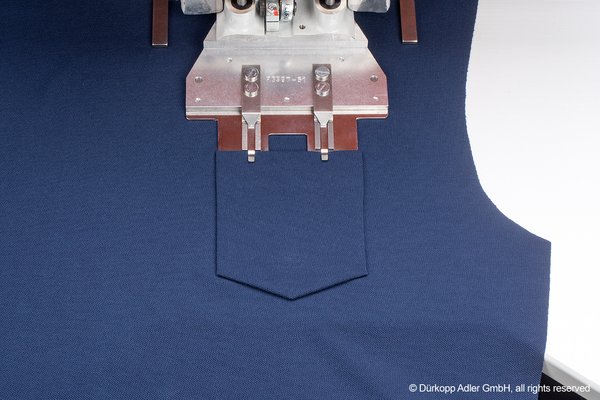

The patch pockets are creased and attached in top quality and with maximum efficiency. Changes of and adaptations to your pocket shapes can be realized easily and quickly. According to the subclass shirt pockets or jeans pockets can be sewn. Pattern-compliant dressing of stripedand check fabric can be done directly on the sewing unit.on the sewing unit. Unnecessary marking of pockets is eliminated.

Your benefits:

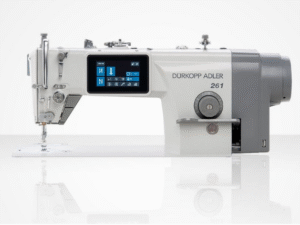

Perfect seam quality in shirts, knitwear, underwear, jeans and workwear etc. Depending on the machine class selected, pockets can be produced in perfect seam quality in shirting, knitwear, denim fabrics and many more. Individual adaptation of the seam programs to different materials is programmable.

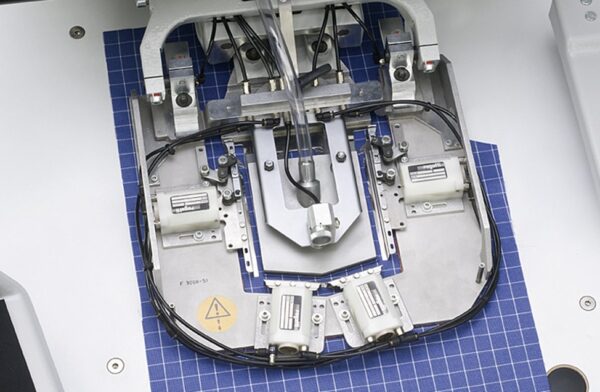

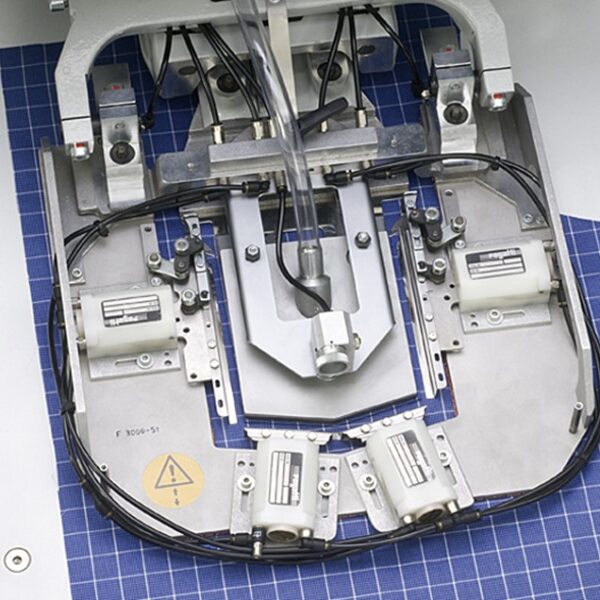

Fully overlapped work cycle: maximum efficiency due to automatic creasing, attaching and stacking. The sewing panel is positioned on the material base and held in place by a vacuum. The pocket cut is placed on the centre slider. After loading the creasing, sewing and stacking are done automatically. The operator can reload the sewing unit while sewing.

Touch panel PC with software (“DACAD”) for the creation and modification of flexible seam programs. Touch-Panel-PC has a Windows® surface with integrated program version of “DACAD” for creating and modifying pocket programs. The user interface is world-wide understandable through selectable, international operator languages. Sewing programs can be transferred to other machines via USB stick. Thanks to the fault diagnosis, service and help functions and easy-to-understand instructions, the maintenance and modification of the machine is made easy for the operator.

Easy operation and short training times.

Exact seam contour due to fine adjustment of the seam programmes (creasing, corner and tack stitches) directly at the sewing unit

Sequences for the alternate processing of the right or left pocket possibleIndividual adaptation of sewing programs for different materials

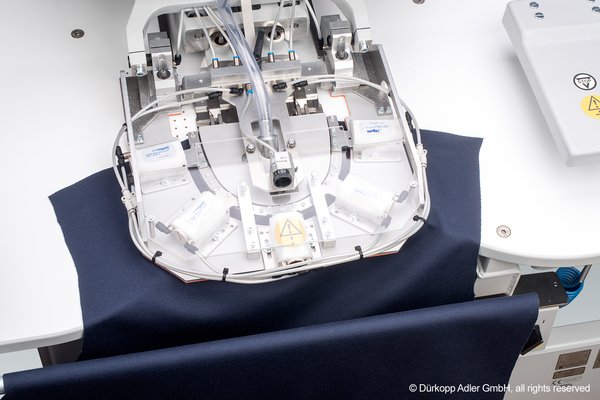

Ergonomic workplace (alternatively for sitting or standing operation). The workstation is ergonomically designed and is suitable for both seated and standing operation. The loading area is designed to ensure an optimum view of the sewing material. Thus, striped and checkered material can also be optimally aligned.

Quick change kit for creasing sets and transfer devices. Quick and easy change of style sets due to guided instructions via the control panel and automatic release of the parts to be changed by the machine. No tool is required for a change of style set.

Single and double seams, additional and decorative seams for individual design. Pocket shapes and tacks

In addition to various pocket shapes (depending on the pattern), single and double seams, whether conical or two-needle, can also be programmed. Furthermore, it is possible to sew bartacks directly on the machine. This eliminates the need for an additional operation after the pockets have been attached.

Flexible stacking system for differing material sizes

Pocket style sets of the sewing units 806-111-01, 806-121-01 and 805 (requires optional set of parts) can be used

Processing of patterned and plain fabric.

Processing method Shirt (uni):

The front piece is positioned on the material base and fixed by a vacuum. The pocket cut is positioned on the center slide. After confirming the start button, the pocket is automatically folded, sewn and stacked.

Processing method shirt ( checkered or patterned fabric):

The front piece is positioned on the material base and fixed by a vacuum. The pocket cut is positioned on the center slide. To align the pattern, the center slide is lowered and the vacuum is switched off. The front part can be aligned according to the pattern and then the vacuum switched on again. After confirming the start button, the pocket is automatically folded over, sewn and stacked.

Example of use:

· Blouses and shirts

The front piece is positioned on the material base and fixed by a vacuum. The pocket cut is positioned on the center slide. After confirming the start button, the pocket is automatically folded, sewn and stacked.

Performance examples in 480 min

approx. 2.400 shirt pockets

· Jeans and workwear

Processing method jeans or workwear: 806N-111-10

The heavy sewing head allows the processing of medium-weight fabrics and thread sizes up to a thickness of 12/3.

Performance examples in 480 min.: 806N-111-10 – approx. 1.800 jeans pockets (with double seam and bartack)

The sewing piece is positioned on the material base and fixed by a vacuum. The pocket cut is positioned on the center slide. After confirming the start button, the pocket is automatically folded, sewn and stacked.

· Blouses and shirts ( checkered or patterned fabric)

Processing method shirt ( checkered or patterned fabric) 806N-121-10:

The front piece is positioned on the material base and fixed by a vacuum. The pocket cut is positioned on the center slide. To align the pattern, the center slide is lowered and the vacuum is switched off. The front part can be aligned according to the pattern and then the vacuum switched on again. After confirming the start button, the pocket is automatically folded over, sewn and stacked.

Performance examples in 480 min.:

– Approx. 1,800 shirts pockets (patterned fabric)

· Creasing and attaching of pockets with flap – Automatic flap attaching

Optionally, the 806N-121-10 can be equipped with a device for flaps. This allows one-piece or two-piece flaps to be sewn on and overstitched during the sewing process.

· Custom made for large garment

The machine has an enlarged sewing material support for large blanks. The distance between the creasing and sewing station is 1,100 mm. The cut pieces can be shifted beyond the sewing material rest. Pockets up to 300 x 300 mm can be processed. Furthermore, the machine includes an extra-wide stacker for large cut pieces. Uniform stacking is possible due to the wide ejector.

· Custom made for tubular knitwear

The special design for tubular knitwear is equipped with a specially curved table top. Special material clamps prevent the material from slipping. In addition to pockets, sweat sheets can also be processed.

Performance examples in 480 min.: 806N-121-10 – approx. 2,000 pockets or 1,800 sweat sheets.

|

Feature |

806N-111-10 |

806N-121-10 |

|

Stitch Length |

3.5 mm |

3 mm |

|

Stitches/min. |

3,800 |

4,000 |

|

Sewing Material |

Medium/Medium-heavy (M / MS) |

Light/Light-medium (L / LM) |

|

Sewing Field Size |

220 x 230 mm |

200 x 220 mm |

|

Hook |

Vertical hook, large (XL, Ø 28 mm) |

Horizontal hook, small (S, Ø 22mm) |

|

Typical Use |

Jeans and workwear pockets |

Shirt pockets (plain or patterned) |

Additional points to note:

- Both models are single-needle lockstitch (301) machines with automatic thread trimmers, needle thread monitors, pneumatic needle cooling, flip stackers, and program control with a touch screen.

- Machines are CNC-controlled sewing units designed for automatically sewing pockets, but they are optimized for different fabric weights and types.

- The 806N-111 is designed for sewing pockets on heavier materials like jeans and workwear.

- The 806N-121 is designed for sewing pockets on lighter materials like shirts and knitwear.

- The 806N-121 is also optimized for sewing circular knitwear.

- Both machines offer high efficiency due to features like automatic creasing, attaching, and stacking.

- Both models use the same “DACAD” software for creating and modifying seam programs.

- Pocket style sets can be interchanged between the 806N-111-01, 806N-121-01, and 805 (with an optional parts set)

| Stitch type | Lockstich |

|---|---|

| PLATFORM TYPE | Flat bed |

| Segment of production | Garment |

| Manufacturer |

Reviews

There are no reviews yet.