Vilnius, T. Žebrausko g. 7

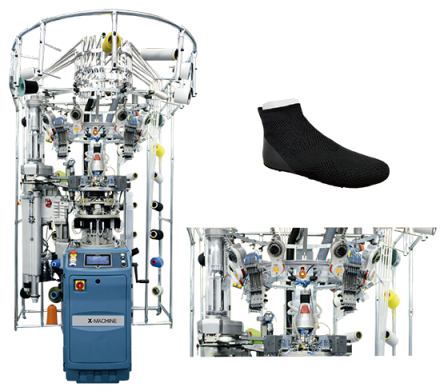

Elettrotecnica BC Mod BC2018X Machine for the realization of the upper in 3D

Machine for the realization of the upper in 3D.

Single cylinder electronic knitting machine with 4 reciprocating-motion feeds and 2 points of selection per feed and rotation sense, which knits various technical Intarsia items. This system, patented, allows the possibility of patterning on all 4 feeds giving high definition and a sharpness of colour.

MAXIMUM SPEED:

180 rpm in unidirectional motion.

CYLINDER SELECTION:

Selection on the cylinder through actuators with 12 levels (8 in total: two for each feeder for both rotation senses).

SINKER CAP SELECTION:

Actuators with 6 levels (4 in total per sinker selection).

STRIPPING YARNFINGERS:

6 multi-position yarnfingers per feed.

TRAPPER FOR BARE AND COVERED ELASTIC YARN:

3 trappers per feed.

DIAL JACKS AND YARN CUTTER:

Yarn cutter saw release with up and down dial movement, driven by step motor to reposition the saw blade height.

SUCTION SYSTEM:

Take-down aspiration by 2 suction fans or a central suction system.

Items suction tube Ø 60 mm.

Items transfer tube Ø 60 mm.

Air limiting valve with electronic incremental programming

STITCH CAMS:

Stitch formation adjustment by step motors, independent on each feed. Possibility of loop widening, tightening and shading on the same area and/or course.

Step motor to reposition cylinder height.

On board items sizing, adjustable in both cm. and inches.

MAIN KNITTING POSSIBILITIES:

Single or double welt carried out by dial jacks, in several selections, with knitted and laid-in elastic yarn. With 4 feeds on the same course: patterns and/or supports placed with Intarsia technology, eliminating cut yarns inside the item. Every knitted pattern has up to 3 technical ways. 4 feed selectable terry in both rotational senses.

SINKER CAP:

Closed-tracks cam box with angle cams position driven by a step motor for precise loop/stitch control

YARN FEEDERS:

6 mechanical yarn recoveries per each feeder (24 in total).

OPTIONAL:

Elastic feeders with step motor.

EFS920 Memminger – IRO for yarn recovery.

YARN SENSORS:

Latest generation of optical yarn sensors.

CREEL:

With rear yarn rack.

LUBRICATION:

Pneumatic pump with oil recycling.

MACHINE MOVEMENT:

Torque Motor.

ELECTRONIC CONTROLLER:

Integrated ‘quad core’ from Dinema for the serial checking of all electronic systems. Latest generation of graphic display with a

colour touch screen.

PROGRAMMING:

Software S.I.S. Plus with totally graphical integrated programming.

TECHNICAL DETAILS

Diameter: 4″

Needle No.: 96 – 108 – 120 – 120 – 132 – 144

Needle Gouge (GG): 18 – 18 – 18 – 24 – 24 – 24 –

Machine Gouge (GG): 8 – 9 – 10 – 10 – 11 – 12

| Segment of production | Shoes |

|---|---|

| Manufacturer | |

| Type of machine | Textile machines |

Reviews

There are no reviews yet.