Vilnius, T. Žebrausko g. 7

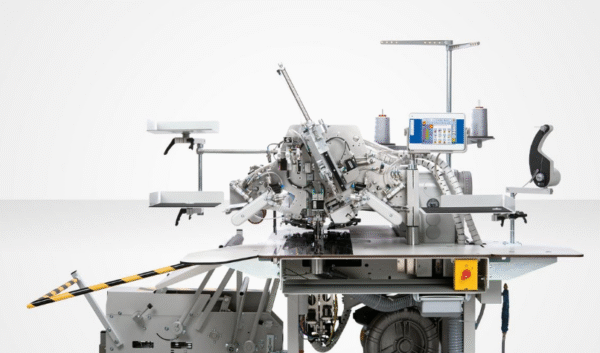

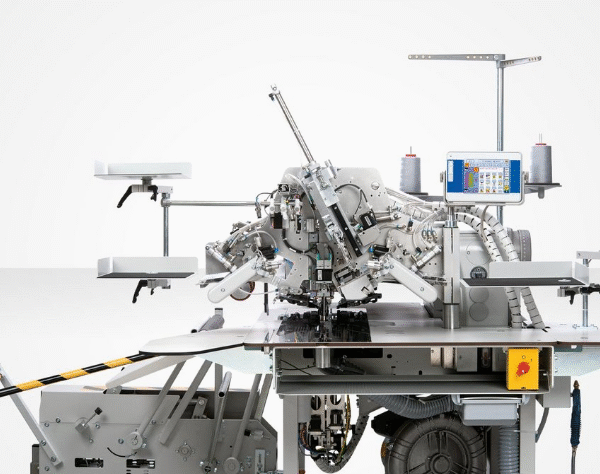

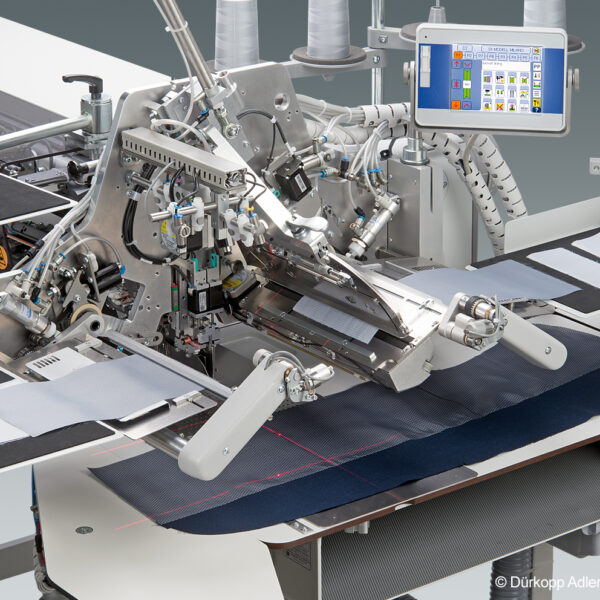

Duerkopp Adler 755 B / 756 B – Sewing units for runstitching straight and slanted pocket openings with fully automatic feeding device

| 755 B / 756 B | Sewing units for runstitching straight and slanted pocket openings with fully automatic feeding device |

Introduction:

The 755 B and 756 B sewing units are designed to revolutionize the production of runstitched straight and slanted pocket openings. These machines significantly streamline the process, offering fully automated feeding of piping strips and optional automation for pocket flaps and bags. With their advanced features and focus on efficiency, these units can save you up to 50% in pocket manufacturing time compared to traditional manual methods. These are the ideal solution if you are seeking to rationalize your production of piped pockets.

Key Benefits:

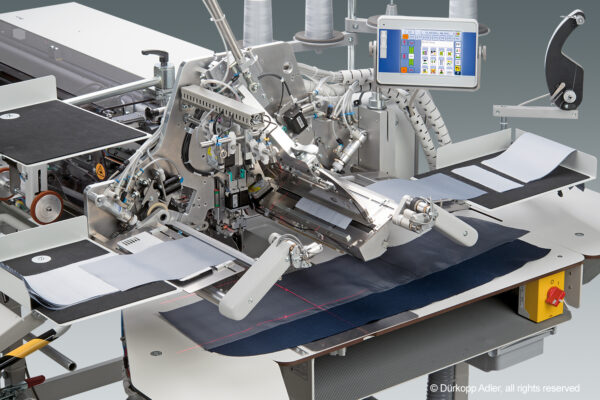

- Fully Automatic Feeding: Achieve a seamless workflow with automated feeding for piping strips, flaps, and pocket bags. This allows for a fully overlapped operation; while one pocket is being sewn, the piping ends can be cut, and the components for the next pocket can be loaded, drastically reducing idle time.

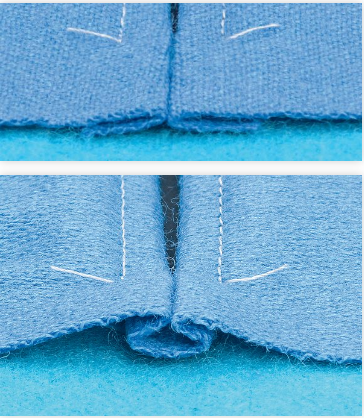

- Automatic Piping End Cutting: Enhance pocket quality and productivity with automatic piping end cutting. This not only eliminates manual cutting, which reduces cycle time by 20%, but also minimizes material layers, preventing marks and shiny spots from ironing. The precise cutting also ensures perfect pattern matching with striped fabrics.

- Significant Time Savings: Experience up to 50% reduction in production time by combining fully automatic component feeding with automatic piping end cutting.

- Ergonomic Design: The optimized feeding devices allow for comfortable and unobstructed loading of piping strips onto the support table, enhancing the user experience.

- Pocket Bag Over Flap Option: For processing jacket outside pockets, a specialized set allows for the simultaneous attachment of two pocket bag halves and a flap, further eliminating manual steps, saving time and improving efficiency. This method, particularly when processing long pocket bags with flaps, can yield 20% time savings over conventional methods.

- Improved Material Handling:

- New Flap Clamps: Additional flap clamps with adjustable stops simplify the application of long pocket bags over flaps.

- Pocket Bag Deflector: A pocket bag deflector ensures the safe roll-out of the jacket into the stacker.

- Programmable Flap Stop: A programmable flap stop facilitates quick changes in flap widths.

- Unique Programmable Material Adjustment: Easily adjust for different material thicknesses with one touch. The programmable height adjustment of the folding guide plates and folder ensures optimal adaptation to varying materials, eliminating mechanical adjustments.

- Enlarged Material Passage: The improved folder system allows for quick and easy exchange of folder and sole inserts, further reducing downtime.

- Adjustable Needle Distances: Choose from needle distances ranging from 8 to 20 mm.

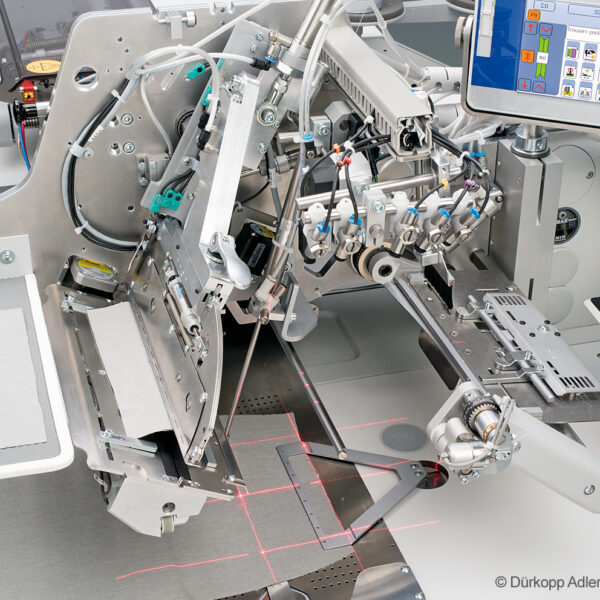

- Programmable Hook Block Adjustment: Quickly and automatically adjust the left and right hook blocks when changing the needle distance, significantly reducing the time spent on machine adjustments and improving flexibility when dealing with different pocket widths.

- Programmable Needle Feed: Achieve superior seam quality, especially with difficult-to-sew materials like stretch fabrics, patterned materials, coats, and leather. The transport length is adaptable and storable, and a special knitwear mode is available.

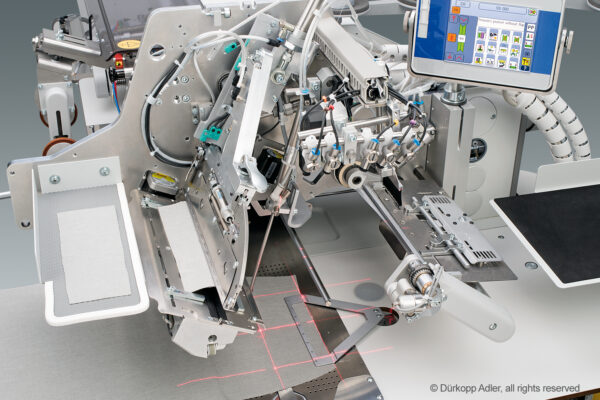

- Programmable Laser Marking Lamps: Stepper motor controlled laser marking lamps (optional) in both longitudinal and transverse directions allow for precise marking, eliminating mechanical adjustments during model changes.

- Stepper Motor Controlled Transport Clamp: Programmatically adjustable transport clamps with material spreading accommodate a wide variety of materials. It enables automatic changeover from double to single piping and can save programming for different material thicknesses.

Specific Features:

- Automatic Corner Knife Station: For straight pockets, and a multi-function corner knife station for both straight and slanted pockets.

- Center Knife with Counter Knife: Separately motor-driven.

- Notching of Piping Ends: For clean and precise finishes.

- Thread Trimmer, Needle Thread Monitor, and Bobbin Thread Monitor: Ensure smooth and consistent operation.

- Suction Device: For exact fabric positioning.

- Flip Stacker and Bundle Clamp: For efficient material handling.

- User-Friendly Control Panel: Program control with OP7000 operating panel featuring a graphic display and touch screen.

Examples of Use:

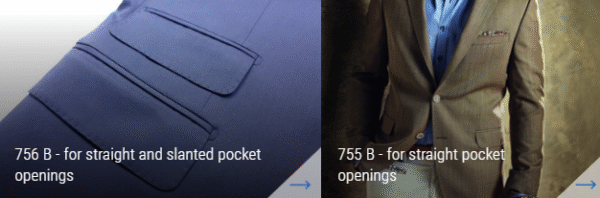

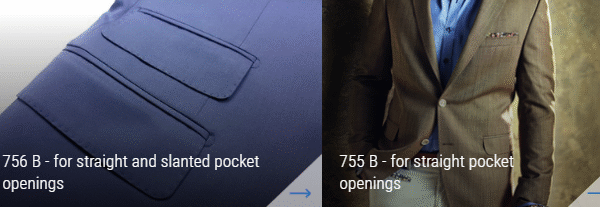

- 756 B: Ideal for straight and slanted pocket openings, commonly used for double piped pockets with flaps in jackets (approx. 1,600-2,000 pockets/480 minutes).

- 755 B: Perfect for straight pocket openings, frequently used for single or double piped pockets in hind trousers (approx. 2,000-2,400 pockets/480 minutes), but can also handle double piped pockets with flaps in jackets (approx. 1,600-2,000 pockets/480 minutes).

- 755 B: Suited for lining pockets in jackets or blazers, handling single or double piped pockets (approx. 1,400-1,600/480 minutes)

Attachment for Endless Zippers:

- Process endless zippers with ease (optional), ideal for applications like trouser pockets, rider pants pockets, and sportswear. Special folders with zipper attachment are available in a variety of types based on needle distances and zipper sizes (to be ordered separately). The “Programmable Needle Feed” is highly recommended for optimal results.

Technical Specifications:

- Stitch Length: Adjustable from 0.5 to 4.5 mm.

- Sewing Material: Suitable for light, medium, and heavy materials.

- Seam Length: Ranges from 20 to 220 mm.

- Twin Needle: 8 mm (disengageable).

- Stitch Type: Lockstitch (301).

- Hook Type: Vertical hook, large.

Features & Technical Details

| FEATURE | TECHNICAL DETAILS (755 B) | TECHNICAL DETAILS (756 B) | NOTES |

|---|---|---|---|

| Stitch Length | 0.5 – 4.5 mm | 0.5 – 4.5 mm | Adjustable stitch length range |

| Stitches per Minute (spm) | 3,200 spm | 3,000 spm | Maximum sewing speed |

| Sewing Material | LM / M / MS (likely indicating Light, Medium, and Medium-Stiff material types) | LM / M / MS (likely indicating Light, Medium, and Medium-Stiff material types) | Supported material types |

| Seam Length | 20-220 mm | 20-220 mm | Range of seam length capability |

| Twin Needle | 8* mm (Likely indicates gauge of twin needle) | 8* mm (Likely indicates gauge of twin needle) | Distance between twin needles |

| Twin Needle, disengageable | Lockstitch (301) | Lockstitch (301) | Ability to disengage one needle |

| Hook Type | Vertical hook, large (L, Ø 26 mm) | Vertical hook, large (L, Ø 26 mm) | Large hook for more thread capacity |

| Programmable Needle Transport | Yes | Yes | Allows programmable and precise needle movement |

| Clamp Adjustment with Material Spreading | Yes | Yes | Ensures even material feed without wrinkles |

| Thread Trimmer, Automatic | Yes | Yes | Automatic trimming of threads |

| Automatic Corner Knife Station | For straight pockets, freely programmable in the pocket length | For straight or slanted pockets | Automated cutting for clean corners in pocket sewing |

| Multi Function Corner Knife Station | No | Yes | For straight and slanted pockets |

| Centre Knife with Counter Knife | Separately motor driven | Separately motor driven | For precise central cutting |

| Notching of Piping Ends | Yes | Yes | Creates notches at end of piping for easier folding |

| Automatic Feeding of Piping Strips | Yes | Yes | Automated feeding of piping strips |

| Automatic Feeding of Flaps and Additional Parts | Yes | Yes | Automated feeding of flaps or other parts |

| Stitch Condensing, Automatic | Yes | Yes | Automatic reinforcement of beginning/end of seam |

| Needle Thread Monitor | Yes | Yes | Indicates when needle thread is low or broken |

| Bobbin Thread Monitor | Yes | Yes | Indicates when bobbin thread is low |

| Bobbin Thread Control | Yes | Yes | Regulates bobbin thread tension |

| Suction Device for Fabric Positioning | Yes | Yes | Aids precise fabric placement |

| Flip Stacker | Yes | Yes | Automated stacking of completed parts |

| Bundle Clamp with Rest Table | Yes | Yes | Clamp to hold a bundle, table for operator convenience |

| Program Control, Operating Panel | OP7000 with graphic display and touch screen | OP7000 with graphic display and touch screen | Control panel for machine operation |

Conclusion:

The 755 B and 756 B sewing units are comprehensive solutions for manufacturers seeking to optimize their pocket production. By combining cutting-edge automation with precise control and ergonomic design, these machines deliver unmatched efficiency, quality, and versatility. Invest in these units to significantly enhance your throughput and produce high-quality piped pockets with minimal time and effort.

| Stitch type | Lockstich |

|---|---|

| PLATFORM TYPE | Flat bed |

| Segment of production | Garment |

| Manufacturer | |

| Type of hook | Vertical |

Reviews

There are no reviews yet.