Vilnius, T. Žebrausko g. 7

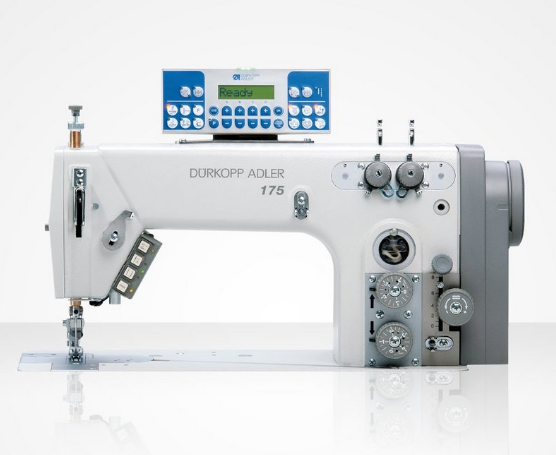

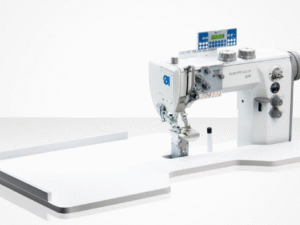

Durkopp Adler 175 / 176 / 179 – Single or double needle chainstitch machine with DIFFERENTIAL FOOT TOP FEED or DIFFERENTIAL BOTTOM FEET

175 / 176 / 179 | Single or double needle chainstitch machine with DIFFERENTIAL FOOT TOP FEED or DIFFERENTIAL BOTTOM FEET

Versatile single or double chainstitch machines

Your benefits at a glance

· 175-141621 Class 175, a double chainstitch machine equipped with differential foot top feed and bottom feed, is particularly suitable for pre-assembly and assembly seams, e.g. seams in lining (with / without piping), sleeve-, back-center seams as well as side and shoulder seams. Whether smooth seams or seams with partial fullness in the upper fabric layer, this machine has no limits.

· 176-141621 The 176, a double chainstitch machine equipped with differential bottom feed, is particularly suitable for seams with partial fullness in the lower fabric layer, e.g. for taping operations and attaching waistbands in transport-critical materials.

· 179-171629 The 179, a single thread chainstitch machine with differential foot-top feed can be used in jacket, blazer and coats productions, operations such as basting of collars, edges, hem, collar peak and collar break, pocket openings etc. simple and convenient. If necessary, a partial fullness can be incorporated in the upper fabric layer.

· Electromagnetic functions such as thread trimmer and sewing foot lifting are standard in the machines

· Constant or partial fullness in the upper / lower fabric layer. Depending on the machine class, fullness can be constantly or partially worked into the lower or upper material layer.

o Class 175, a double chainstitch machine equipped with differential foot top feed and bottom feed, is particularly suitable for pre-assembly and assembly seams, e.g. seams in lining (with / without piping), sleeve-, back-center seams as well as side and shoulder seams. Whether smooth seams or seams with partial fullness in the upper fabric layer, this machine has no limits.

o The 176, a double chainstitch machine equipped with differential bottom feed, is particularly suitable for seams with partial fullness in the lower fabric layer, e.g. for taping operations and attaching waistbands in transport-critical materials.

· 175-141621 – Easy conversion to two-needle machine, needle distances up to 15mm. With the conversion set 175-590074, a simple conversion from single-needle to two-needle is possible. Needle distances up to 15mm can be converted. Application example:

Attaching endless zippers onto fly pieces – therefore the sewing head, which has been converted into a two-needle machine, is equipped with a needle distance of 5 mm.

· High-quality DÜRKOPP ADLER control technology. The machines are equipped with “DAC classic” control system.

· Easy recall of a preset fullness via button. Calling up a preset fullness via button. The 4-button bar attached to the sewing head offers quick access to (from bottom to top):

o Fullness switching

o Second stitch length (depending on machine class)

o Needle up/down position

o Backtack suppression at the beginning / end of the seam

o Pressing the quick access key for fullness, calls up the mechanically preset fullness. This makes it quick and easy to switch between two preset settings.

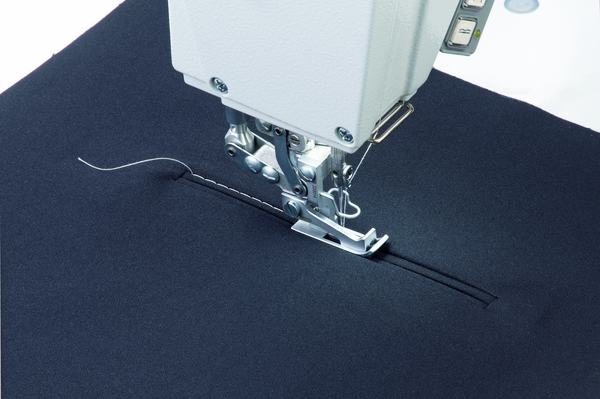

· Marking-free sewing with a patented lightweight lifting system (only 175 and 179)

· Smooth and elastic sewing results, even with transportcritical materials

· Always optimal stitch formation by the automatic adjustment of the lower thread quantity to the stitch length

· Large, flexible application area

Examples of use

· 175-141621 – Close side and shoulder seams. The differential foot top feed allows to work in fullness in the upper fabric layer, which can be recalled by button means of an electro-pneumatic device.

· 175-141621 – Ruffling operations. With intermediate sheet (N900 003601) – for the particularly intensive ruffling of fullness, with an electro-pneumatic device for recalling a preset fullness via button.

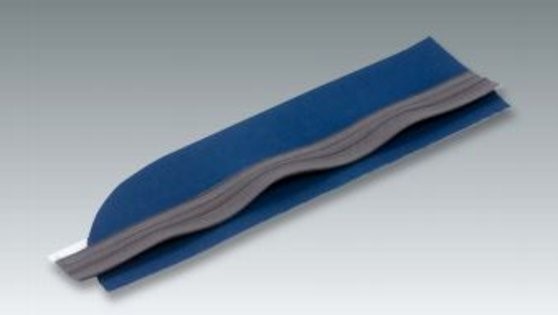

· 176-141621 – Taping operations. Taping operations in the area of jackets, blazers and coats, the 176 reaches a large range of possible applications; for e.g. taping of the front and back parts in the region of the neck, armhole and collar. The tape is then peeled off the roller and guided under the presser foot by means of guides. A special sewing device ensures precise positioning of the tape underneath the presser foot. The differential bottom feed allows to work in fullness in the lower fabric layer, which can be recalled by means of an electro-pneumatic device (0275 590044).

· 176-141621 – Seams with fullness in the lower material ply. For e.g. attaching skirt and trousers waistband. Also for ruffling the lower fabric ply in the children, sports and women’s wear, the stitch type and the feed tpye form an indispensable combination.

· 179-171629 – Basting operations. This single thread chain stitch machine enables uncomplicated and clean stitching in the jacket, blazer and coats production. The differential bottom feed allows to work in fullness in the upper fabric layer, which can be recalled by means of an electro-pneumatic device.

· 175-141621 – Lining seams. A general operation in the area of jacket production is the attaching of front lining to facings (N079 008533 + N900002841). If required, a piping strip can be attached at the same time (E1/N023).

· Attach endless zipper to fly piece. With fullness in the zipper – after conversion of the machine to twin-needle double chainstitch (set of parts 0175-590074) with tape unwinder (0175 590064).

|

175-141621 |

176-141621 |

179-171629 |

|

|

Stitch Length |

4.0 / 8.0 |

6.0 / 4.0 |

8.0 / 8.0 |

|

Stitches/min. |

5,000 |

5,000 |

5,000 |

|

Sewing Material |

L / M / MS |

L / M / MS |

L / M |

|

Needles |

Single needle (two needles-option) |

Single needle |

Single needle |

|

Stitch Type |

Double chainstitch (401) |

Double chainstitch (401) |

Single thread chainstitch (101) |

|

Looper (crossline) |

|||

|

Differential Bottom Feed |

– |

Yes |

– |

|

Bottom & Differential Top Feed |

Yes |

– |

Yes |

|

Fullness Above (Dial Adj.) |

Yes |

– |

Yes |

|

Fullness Above (Foot Adj.) |

Option |

– |

Option |

|

Fullness Above (Hand Adj.) |

Option |

– |

Option |

|

Fullness Below (Dial Adj.) |

Yes |

||

|

Fullness Below (Foot Adj.) |

– |

Option |

– |

|

Fullness Below (Hand Adj.) |

– |

Option |

– |

|

Thread Trimmer |

Yes |

Yes |

Yes |

|

Automatic Sewing Foot Lift |

Yes |

Yes |

Yes |

|

Stitch Condensing & Foot Lift (Pedal) |

Yes |

Yes |

– |

|

Automatic Functions (Light Barrier) |

Option |

Option |

– |

|

Clearance Sewing/Lifting |

A= 6 / B= 9 |

A= 6 / B= 9 |

A= 7 / B= 9 |

|

Program Control – OP1000 |

|||

|

Feature |

175-141621 |

176-141621 |

179-171629 |

|

Air Requirement per Stroke / Air Pressure 0.1 / 6 |

|||

|

Needle System |

934 |

934 |

5463-35 |

|

Needle Size 80-130 |

|||

|

Synthetic 70/3 |

|||

|

Nominal Voltage 1x230V, 50/60 Hz |

|||

|

Rated Power 500 |

|||

|

Weight, Sewing Head (kg) 36 |

|||

|

Weight, Complete (kg) 58 |

|||

|

Packaging Size (L/W/H in mm) 780 / 370 / 790 |

|||

| Stitch type | Chainstitch |

|---|---|

| PLATFORM TYPE | Flat bed |

| Segment of production | Garment / Technical Textiles |

| Manufacturer |

Reviews

There are no reviews yet.