Vilnius, T. Žebrausko g. 7

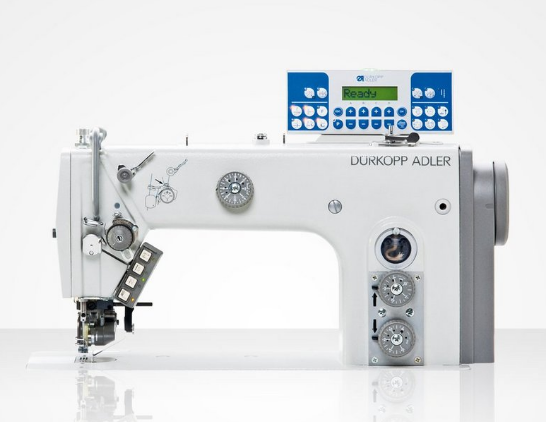

Durkopp Adler 273 / 274 – Single needle lockstitch machines with top puller feed AND NEEDLE FEED

273 / 274 | Single needle lockstitch machines with top puller feed AND NEEDLE FEED

Predestinated for flat seams – even in difficult-to-feed fabrics

The top puller feed machines 273 and 274 are predestinated for flat seams – even in difficult-to-feed fabrics. Even at maximum speed the top puller feed is characterized by its synchronous working method. Supplementary to the bottom feed the material is systematically tensioned during the sewing process due to the additional intermittently operating puller, thus producing a pucker-free seam. Due to the thread nipper the needle thread is pulled to the reverse side of the fabric at the seam beginning. This guarantees an always neat seam beginning. The machines can very easily be converted to bottom- / needle feed machines by lifting the puller out of the working area by hand.

With the triple feed (bottom, needle, top puller feed) the 274 is predestined for displacement-free seams even in pile fabric like e.g. velvet.

273-140342-01 – Bottom feed and top puller feed

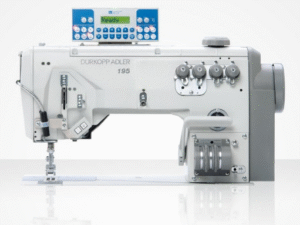

274-140342-01 – Bottom feed, needle feed and top puller feed

Your benefits at a glance

· Flat seams in difficult-to-feed material due to bottom feed and intermittent top puller feed (273)

273-140342-01 Single-needle lockstitch machine with bottom feed and top puller feed for critical-to-feed materials. A height adjustment of the coth presser foot at the face cover is optionally available. Typical applications: Long, straight seams such as topstitching the front edge of the shirt or sewing straight hems of shirts.

· Flat, displacement-free seams due to triple feed – bottom-, needle and top puller feed (274)

274-140342-01 Single-needle lockstitch machine with bottom feed, needle- and top puller feed for critical-to-feed materials and displacement-free seams. The 274 is equipped with the height adjustment of the coth presser foot at the face cover as standard. Typical applications: Long, straight seams and processing of high-pile fabrics such as velvet, cordery or plush.

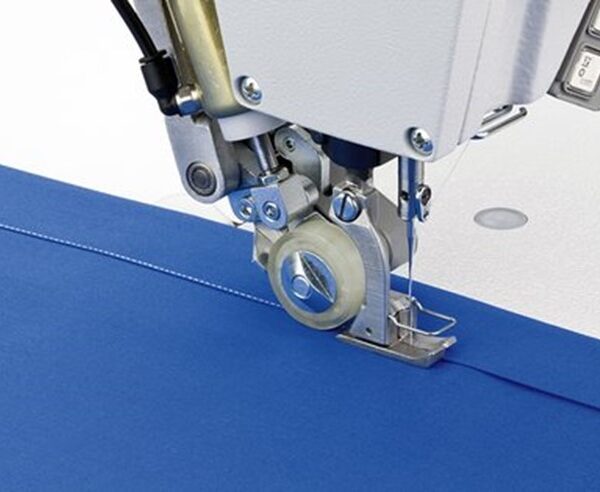

· Top puller feed with constant speed, working extremely close behind the sewing food. The puller is placed directly behind the presser foot and thus very close to the needle (28.5 mm). Therefore it effects the seam directly. Controlled by the sewing drive the puller runs synchronized to the feed dog (adjustable by setting wheel), independent of the stitch length. To avoid fabric jam at the seam beginning, the lowering time of the puller can be programmed.

· Reproducible adjustment of the top puller feed via handwheel, independent of stitch length. Stitch length of the puller: Controlled by the sewing drive, the puller runs synchronously to the feed dog. To change the stitch length of the puller, the puller stitch length can be easily set independently of the stitch length for the seam using an adjusting wheel. To avoid a material jam at the seam beginning, the puller lowering time can be programmed.

The puller is located directly behind the sewing foot and thus very close to the needle (28.5 mm). It thus has an immediate effect on the seam.

· Top puller feed can be lifted upwards, thus the clearance is equal to that of the 272. For long and straight seams, the puller supports the fabric transport. It can be lifted by a lever. Then the clearance accords to that of a 272 – needle feed machine. Thus, both straight seams and e.g. curves, can be processed perfectly and quickly.

· Height-adjustment of the pressure foot. Provides a floating sewing foot (standard for 274, optional equipment for 273 above high pile material). In order to avoid displacement of the layers in high pile fabrics, the height of the presser foot can be increased with a setting wheel on the face cover. Thus, the foot has an reduced effect on the fabric and ensures an optimal transport without displacement of the fabric layers.

· Neat seam beginning due to thread nipper. The thread clamp enables a clean seam begin and end. It pulls the thread extensions to the back side of the material. Thus the right fabric side is clean without any thread ends, no thread need to cut on the right fabric side.

· Automatic sewing foot lift, thread trimming and backtacking as standard

· Multi-function pushbutton bar for quick access. Ergonomically placed multi-function button for

-

puller up/down

-

seam backtacking

-

needle up/down in the seam

- single stitch and backtack inversion

· Energy-saving, integrated sewing drive

· Central oil-wick lubrication

· High-quality DÜRKOPP ADLER control technology. DAC classic control with control panel OP1000

-

Electric strength (up to 400 V AC)

-

Extended operating range (190 V AC to 250 V AC)

-

Updatability via various storage media

-

Special energy efficiency by optimum software parameters by means of machine ID technology

-

Freely programmable functions and inputs

-

Seam programming

Examples of use

· Sewing straight shirt hem. Equipped with a folder, the 273 can be used very well for processing straight hems. Hem widths of 5 – 30mm can be realized. The puller achieves absolutely smooth sewing results. The puller is easily adjusted via a handwheel on the sewing head.

· Processing of high-pile fabrics (velvet or plush) Velvet processing poses a challenge to every garment manufacturer. The problem with processing velvet and other pile fabrics is that the pile is pressed down by the action of the sewing foot pressure during the transport process. In this process, the pile pushes into each other. Thelayers of fabric shift unintentionally in relation to each other. This makes it difficult to achieve a seam with equal edges and lengths. With the 274 in connection with an intermediate plate (N900 003601) the pile is separated from each other during the sewing process. The puller takes over the transport of the material and the foot pressure can be reduced to a minimum by means of the flexible height adjustment. The unwanted shifting of the fabric layers is thus prevented.

· Long straight seams. The top puller feed machines 273 and 274 are predestinated for flat seams – even in difficult-to-feed fabrics. Even at maximum speed the top puller feed is characterized by its synchronous working method. Supplementary to the bottom and needle feed (depends on the class) the material is systematically tensioned during the sewing process due to the additional intermittently operating puller, thus producing a pucker-free seam.

· Topstitching shirt front edge. The 273 is recommended for topstitching the shirt button (hole) placket. Due to the puller in combination with the bottom feed, the machine achieves excellent material feed and a perfect sewing result, especially for long and straight seams.

· Stitch waistband. The 274 is the ideal machine for topstitching straight and curved skirt and trouser waistbands. With different sewing feet waistbands can be stitched through in the seam shadow of the waistband edge or on the waistband edge with a distance of 1.6 mm. Depending on the requirements Dürkopp Adler offers the right sewing foot for a perfect sewing result.

Features Technical Details

273-140342-01 – Bottom feed and top puller feed

274-140342-01 – Bottom feed, needle feed and top puller feed

· Seam backtacking, sewing foot lift and thread cutting, pedal-controlled

· Disable backtacking, needle up/down and intermittent tacking, actuated by hand

· Thread nipper for a neat seam beginning

· Clearance when lifting, electro magnetic – 6mm

· Program control, operating panel OP1000

· Integrated DA-direct drive

· Stitch length 4,0 / 7,0

· Sewing speed Stitches/min. 5.000

· Sewing Material L / M

· Single needle / Lockstitch (301)

· Horizontal hook, small (S, Ø 22mm)

Features Technical Details

Air requirement per stroke / Air pressure 0,2 / 6

Needle system 134 / 797

Needle size 70-120

Synthetic thread 30/3

Cotton thread 20/3

Flat bed machine with clearance C= 285 / D = 115

Nominal voltage 1x230V, 50/60 Hz

Rated power 500

Weight, sewing head 33/35

Packaging size (Length, Width, Heigh) 780/370/790

| Stitch type | Lockstich |

|---|---|

| PLATFORM TYPE | Flat bed |

| Needle system | 134 |

| Segment of production | Garment / Technical Textiles |

| Manufacturer | |

| Type of hook | Horizontal |

Reviews

There are no reviews yet.