Vilnius, T. Žebrausko g. 7

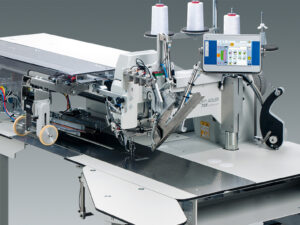

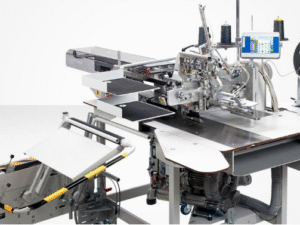

Durkopp Adler 550-12-33/34 – The programmable workplaces for ruffling and trimming

550-12-33/34 | The programmable workplaces for ruffling and trimming

Highest precision and efficiency

The ruffling of single or multi-layered items is, because of ist strong influence on style and further processing, on of the most important and most difficult tasks in the manufacture of home and car upholstery. Precise execution of the ruffling processes when working with the most varied and difficult materials places the highest demands on equipment performance parameters.

The programmable ruffling stations of the class 550-12 with robust, medium-weight double-chainstitch machine heads are characterized by strenght of performance, great flexibility and a consistently high standard of quality.

Superb performance parameters, programmability, adaptable extra functions and basic settings as well as quality- and performance-enhancing optional equipment guarantee the availability of the 550-12 for the entire application spectrum.

Your benefits at a glance

High ruffling intensity due to innovative stepping motor technology and control technology

Consistent, finely dispensed ruffling graduations

Reproducible sewing results via seam programming

Precise, neat trimming for trouble-free further processing of bulky filling material due to solid edge trimmer 550-12-34

Perfect sewing result thanks to the automatic adjustment of the electronic thread tension to the ruffling value

Examples of use Subclasses

550-12-33 – w/o edge trimmer

550-12-34 – edge trimmer 4,5 mm

Close to the edge ruffling of leather parts; sewing equipment for 4,5 mm seam distance, reinforcement tape feed from above and edge guide for guiding the edge of the sewing material

Joining and ruffling of cover parts and padding material with simultaneous trim

Subclass Specifications

|

Feature |

Value |

|

Stitch length |

3-6 |

|

Stitches/min. |

3,000* |

|

Sewing Material |

M / MS |

|

Stitch Type |

Double chainstitch (401) Looper (crossline) |

|

Feed Mechanism |

Differential bottom feed and differential, alternating foot top feed |

|

Sewing Application |

Flat sewing, fullness above and below, flat sewing |

|

Edge trimmer |

4,5 |

|

Sewing foot lift |

pedal controlled |

|

Stroke of the alternating sewing feet |

2-7 |

|

Clearance when Sewing/Lifting |

A= 10 / B= 15 |

|

Storage capacity for setups/seam programs |

999 |

|

Individual programmable complex seam sections |

30 |

|

Feature |

Value |

|

Air Requirement per Stroke |

0.8 |

|

Air Pressure |

6 |

|

Needle System |

933 |

|

Needle Size |

90-160 |

|

Synthetic |

20/30 / 30/3 |

|

Dimensions (L x W x H) |

1060 / 600 / 1700 |

|

Flat Bed Clearance (C/D) |

C=281 / D=110 |

|

Nominal Voltage |

1x230V, 50/60 Hz |

|

Rated Power |

375 |

|

Weight, Complete |

130 |

| Stitch type | Chainstitch |

|---|---|

| PLATFORM TYPE | Flat bed |

| Segment of production | Automotive / Upholstery / Technical Textiles |

| Manufacturer |

Reviews

There are no reviews yet.