Vilnius, T. Žebrausko g. 7

Durkopp Adler 650-10 – Optimized work station for setting sleeves

650-10 | Optimized work station for setting sleeves

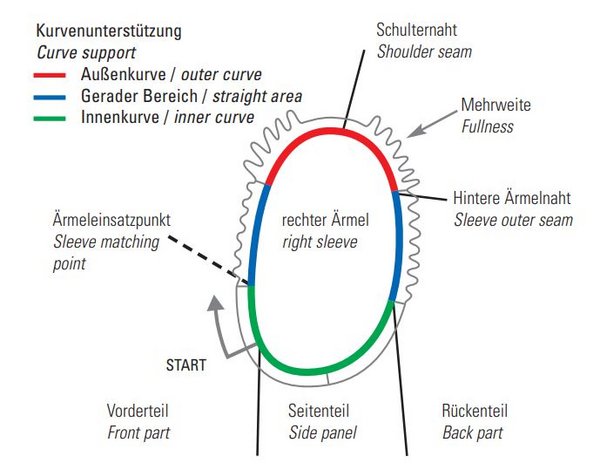

Curve-support for easier handling specially in the sleeve head

Sleeve setting is one of the most difficult sewing operations in the clothing industry. The demands on the operator with regard to dexterity and knowledge of production technology are extremely high.

When using the sleeve setter 650-10 a large part of the difficult handling is taken over by the machine by means of the curve support function. Sewing is simplified considerably, the training periods are shortened essentially and performance as well as quality are increased.

Your benefits at a glance

· Curve support

When using the sleeve setter 650-10 a large part of the difficult handling is taken over by the machine by means of the curve support function. Sewing is simplified considerably, the training periods are shortened essentially and performance as well as quality are increased.

Working method “standard armhole”:

Own programs can be created quickly and easily according to the specifications of the designer. It is possible to work with or without seam length measurement. The inserting of the sleeve head is programmed via the parameter “curve support” (see example of a program with 5 steps)

· Finest fullness nuances via step motor-controlled belt transport to handle sleeve fullness even in most difficult fabrics

· Programming in steps

Thread tension programmable per step, foot pressure and alternation for perfect seams independent of the material thickness, e.g. when processing epaulettes

· Teach-in

Easiest programming possible by ‘teach-in’ procedure and automatic mirroring for the second sleeve. The simple user guidance by means of internationally comprehensible symbols allows a quick program creation also for less experienced operators. Programs are created, mirrored and graded by “teach-in procedure”. The fully automatic linear grading does not require any “expert knowledge of grading”. The desired size is chosen quickly and easily by fingertip. Own seam programs can be stored and transferred to other machines by USB flash drive. The operator chooses the desired size and the program runs fully automatically. This facilitates the handling and the training times of the operators are reduced considerably.

· Ergonomically designed work station for fatigue-free working with integrated LED sewing light

· Short training times due to easiest operation

· All functions are electronically controlled – no compressed air required

· Operating panel OP7000

The touch screen with coloured graphic display of the seam course clearly shows the current program. All important parameters as e.g. fullness, curve support, thread tension, stitch length etc. are easily readable and programmable.The simple user guidance by means of internationally comprehensible symbols allows a quick program creation also for less experienced operators. Programs are created, mirrored and graded by teach-in procedure. The fully automatic linear grading does not require any expert knowledge of grading. The desired size is chosen quickly and easily by fingertip. Own seam programs can be stored and transferred to other machines by USB flash drive. The operator chooses the desired size and the program runs fully automatically. This facilitates the handling and the training times of the operators are reduced considerably.

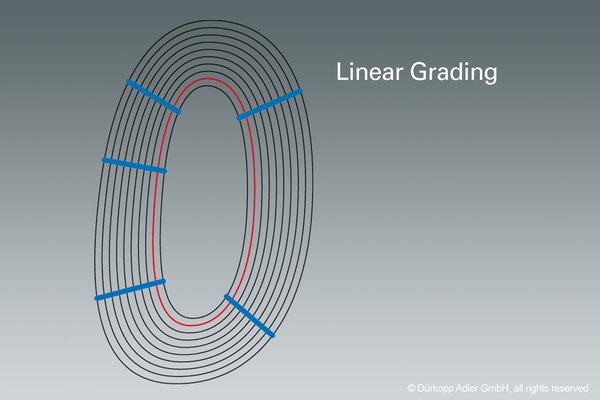

· Sizes and automatic gradings

Programming in the size of your choice – standard grading values automatically calculate the program for every size.

· Linear grading:

Grading will be done proportionally in every step with the same preset percentage value.

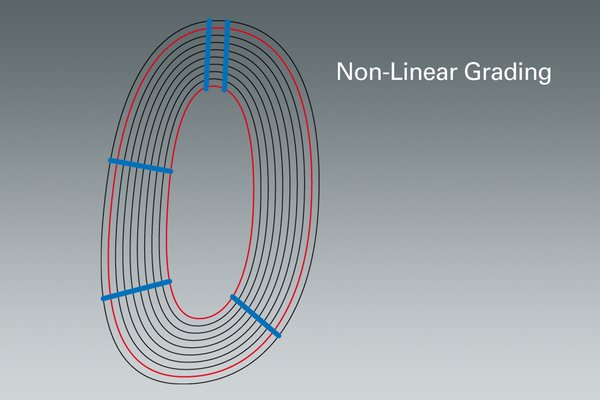

· Non-linear grading:

Grading will be done only in selected steps, some steps are without grading.

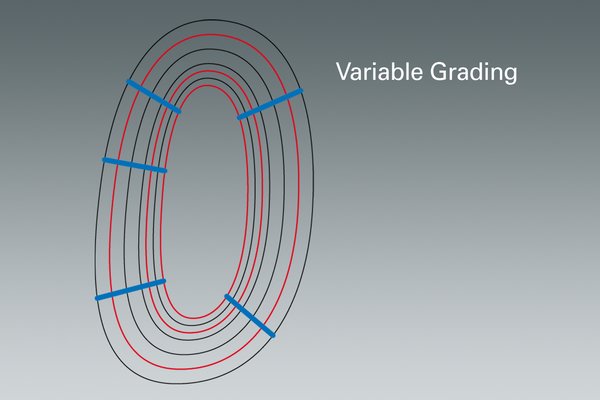

· Variable grading:

Most flexible grading, only the required steps will be graded. The grading factor may be varied, from a certain size onwards, e.g. increased.

Examples of use:

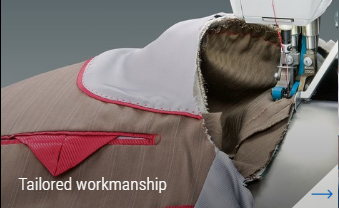

· Tailored workmanship

Sleeve setting in most difficult materials – sleeve head not pre-ruffled, without sleeve head roll.

Performance examples in 480 min.:

Approx. 170 – 250 men’s jackets / ladies’ blazers

(depending on application: sleeves not pre-ruffled / sleeves pre-ruffled)

· Engineered processing method

Sleeve setting in most difficult materials with pre-ruffled sleeve heads – simultaneously with the sleeve head roll.

Performance examples in 480 min.:

Approx. 170 – 250 men’s jackets / ladies’ blazers

(depending on application: sleeves not pre-ruffled / sleeves pre-ruffled)

· Typical application for ladies‘ outer wear

For the special requirements of extremly small armholes and flat seams during processing of light fabrics, such as chiffon or cotton, we recommend specially designed sewing equipment E3 with right transport foot offset to the rear.

Technical specifications

|

Feature |

Technical Details |

|

Model |

650-10 |

|

Stitch Length |

1.5 – 4.0 mm |

|

Stitches per Minute |

4,000 |

|

Sewing Material |

L / M (Likely indicates light/medium weight fabrics) |

|

Needle Configuration |

Single Needle |

|

Stitch Type |

Lockstitch (301) |

|

Hook Type |

Horizontal, Small (S, Ø 22mm) |

|

Feed Mechanism |

Belt Bottom Feed and Belt Top Feed |

|

Fullness Adjustment |

Fullness Above & Fullness Below |

|

Thread Trimmer |

Yes |

|

Seam Backtacking |

Yes |

|

Automatic Sewing Foot Lift |

Yes |

|

Curve Support Function |

Step Motor Controlled Upper Belt Feed |

|

Clearance |

A= 4 mm / B= 12 mm (Sewing/Lifting) |

|

Programmable Thread Tension |

Yes |

|

Control System |

Program Control, Operating Panel OP7000 with graphic display and touch screen |

|

Sewing Light |

Integrated LED with dimmer |

|

Drive System |

Integrated DA-Direct Drive |

|

Feature |

Value |

|

Needle System |

134-35 |

|

Needle Size |

70-100 |

|

Dimensions (L/W/H) |

1320 / 750 / 1490 |

|

Post Bed Machine with Clearance |

– / – |

|

Nominal Voltage |

1x230V, 50/60 Hz |

|

Power Consumption |

1.0 |

|

Weight, Sewing Head |

81 |

|

Weight, Complete |

95 |

|

Synthetic |

150/3 – 50/3 |

| Stitch type | Lockstich |

|---|---|

| PLATFORM TYPE | Post bed |

| Needle system | 134-35 |

| Segment of production | Garment |

| Manufacturer | |

| Type of hook | Horizontal |

Reviews

There are no reviews yet.