Vilnius, T. Žebrausko g. 7

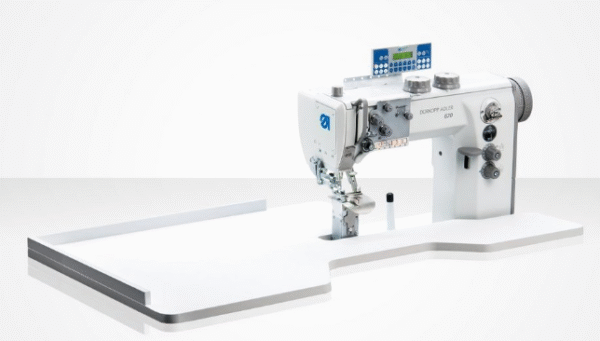

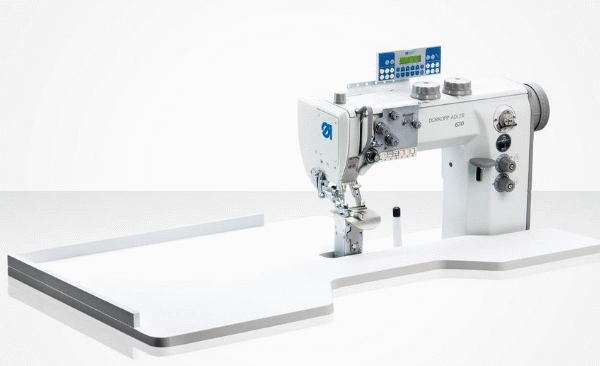

Durkopp Adler 680 – Optimized workstation for attaching shoulder pad and body lining

680 | Optimized workstation for attaching shoulder pad and body lining

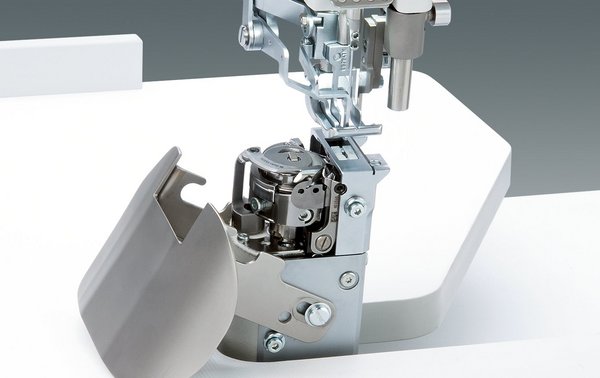

Stitch loosening device for perfect shoulder pads

The optimized workstation 680 is equipped with an edge trimmer, bottom, needle and alternating foot top feed, switchable fullness chooseable from top or bottom and stitch loosening device. The post of the machine is located on the left side for easy handling when basting the body lining into the arm hole with simultaneous trimming of the shoulder pad.

Your benefits

· For a secured sewing start, a low thread tension and stitch condensing can be switched on.

· Material thickness detection

The automatic material thickness detection scans the material thickness via a sensor and is switched on automatically. It can be programmed for symmetrical and asymmetrical shoulder pads with 2 different values within one seam. Depending on the programmed value, it automatically switches on the machine’s additional functions – stitch loosening function, second stitch length, second foot stroke height and second thread tension. This guarantees a consistent volume and soft feel of the shoulder pad.

· Knee switch for manual activating of the stitch loosening device, the 2nd stitch length and the 2nd foot stroke

· Switchable functions

2. stroke height of the alternating foot top feed for easier sewing over the shoulder pad

2. stitch length for sewing over the shoulder pad

2. thread tension for a loose thread tension in the shoulder pad.

· Max. 9 mm stitch length depending on the sewing equipment

· Modern, reliable and network-capable Dürkopp Adler control technology with DAC classic

· The switchable stitch loosening device prevents squeezing when the shoulder pad is sewn through. Thus, the pad retains its volume and soft touch.

· Oil- Lubrication

The central minimum oil wick lubrication is positioned with an eyeglass in the arm. Optionally it can be equipped with a warning light as an oil deficiency indicator (9850 86700)

· Large three-piece vertical hook

Large, three-part vertical gripper Ø 26 mm has 60% higher bobbin capacity for reduced bobbin change. The optimized hook allows lowest thread tension.

· Max. sewing speed of 1.800 stitches/min., the maximum number of stitches depends on the use of the stitch loosening device

· 6-function key bar with quick access and favorite key for the functions: fullness on top, fullness on bottom, 2nd foot stroke, 2nd stitch length, automatic material thickness detection, edge trimmer ON/OFF (only on 680)

· Pneumatic edge trimmer

· The pneumatic edge trimmer of the 680 can be easily switched on and off via a function key. Cutting widths of 6.4 mm, 8 mm and 10 mm can be realized in combination with stitch lengths of 6 or 9 mm.

Example of use:

· Attach shoulder pad and body lining and simultaneosly cutting the fabric edges

The edge cutter cuts the body lining as well as the shoulder pad at the same time while attaching the body lining. Sewing equipment’s with cutting widths of 6.4 mm, 8 mm and 10 mm are optionally available in combination with stitch lengths of 6 or 9 mm. Fullness will be distributed from below in the body lining.

Performance examples in 480 min.:

280 – 340 Body linings

· Attaching sleeve heads / wadding stripes

If the sleeve head is sewn after attaching the sleeves, the practical post bed construction offers an easy handling of the material.

Performance examples in 480 min.:

400 – 460 Pairs of sleeve heads / wadding stripes

· Attach shoulder pads

If the shoulder pad is sewn, the stitch loosening device provides a soft, voluminous shoulder pad.

· Baste ironed shoulder pads

With a max. stitch length of 9 mm, the shoulder pads are basted into the armhole. Thus the volume of the shoulder pad remains unaffected.

Performance examples in 480 min.:

230 – 275 Pairs of ironed shoulder pads

|

Feature |

Technical Details |

|

Stitch Length |

9 |

|

Stitches/min. |

1,800* |

|

Sewing Material |

MS |

|

Needle Type |

Single needle |

|

Stitch Type |

Lockstitch (301) |

|

Hook Type |

Vertical hook, large (L, Ø 26 mm) |

| Option |

Vertical hook, extra large (XXL, Ø 32 mm) |

|

Feed System |

Bottom feed, needle feed and alternating foot top feed |

|

Fullness Adjustment |

Fullness above, adjustable by hand |

|

Fullness below, adjustable by hand |

|

|

Thread Trimmer |

Yes |

|

Edge Trimmer |

6.4 / 8.0 / 10.0 |

|

Knife Stroke, Standard |

10 |

|

Knife Stroke, Adjustable |

Up to 20 |

|

Control for 2 Feed Lengths |

Yes |

|

Seam Backtacking |

Yes (A) |

|

Sewing Foot Lift |

Automatic |

|

Material Thickness Detection |

MTD – Automatic |

|

Manual Stitch Retrieval |

Yes (Second foot stroke, second stitch length) |

|

Clearance (Sewing/Lifting) |

A= 10 / B= 20 |

|

Additional Thread Tension |

Yes (Ma) |

|

Control Panel |

Program control, operating panel OP1000 |

|

Sewing Light |

Integrated LED with dimmer |

|

Oil Maintenance Indicator |

Option |

|

Sewing Drive |

DA-sewing drive |

|

Feature |

Technical Details |

|

Air Requirement per Stroke |

0.69 |

|

Air Pressure |

6 |

|

Needle System |

190 R |

|

Needle Size |

90-160 |

|

Synthetic Thread Range |

50/3 – 120/3 |

|

Dimensions (L/W/H) (mm) |

1350 / 780 / 1350 |

|

Post Bed Machine Clearance (C/D) (mm) |

335 / 297 |

|

Nominal Voltage |

1x230V, 50/60 Hz |

|

Rated Power |

375 |

|

Weight, Complete (kg) |

130 |

| Stitch type | Lockstich |

|---|---|

| PLATFORM TYPE | Post bed |

| Needle system | 134-35 |

| Segment of production | Garment |

| Manufacturer | |

| Type of hook | Vertical |

Reviews

There are no reviews yet.