Vilnius, T. Žebrausko g. 7

Elettrotecnica BC Mod 2088 PSTS Conveyor belt cold conditioning unit

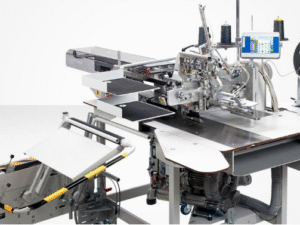

MOD. 2088 PSTS – PROGRAMMED BELT CONVEYOR COOLING UNIT

The programmed cooling unit allows for rapid cooling of all previously heat-treated footwear, solving the problems arising fr om fast work cycles.

It accelerates the stabilization time of footwear and the polymerization time of water-based adhesives, ensuring perfect bonding.

It cools and stabilizes soles and shoes produced by PU machines in a short time.

Compatible with all work island systems.

The presence of the color operator panel makes it easy for the operator to use.

It is easier for the operator to have a series of materials already configured and ready to use.

The new system features work cycles wh ere it is possible to set the machine to load and unload from the same side.

Optimization comes from extra programmed ventilation, in order to obtain maximum cold stabilization.

The program includes a function that automatically calculates the shoe residence time based on the type of material and productivity.

Technical data

MAXIMUM PRODUCTION: approx. 1000 pairs in 8 hours

DIMENSIONS: cm 108 x 206 x 157

NET WEIGHT: Kg. 520 POWER CONSUMPTION: 5.2/3 kW

| Segment of production | Shoes |

|---|---|

| Manufacturer | |

| Type of machine | Cold stabilizers |

Reviews

There are no reviews yet.