Vilnius, T. Žebrausko g. 7

KL 115

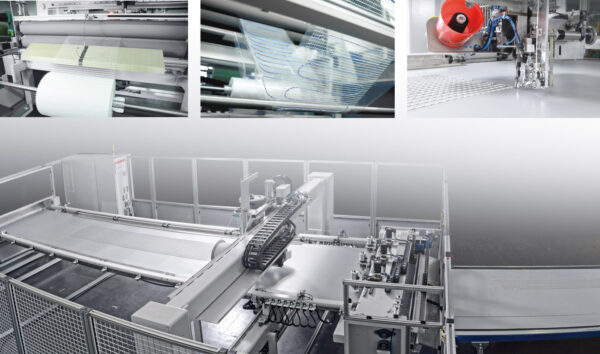

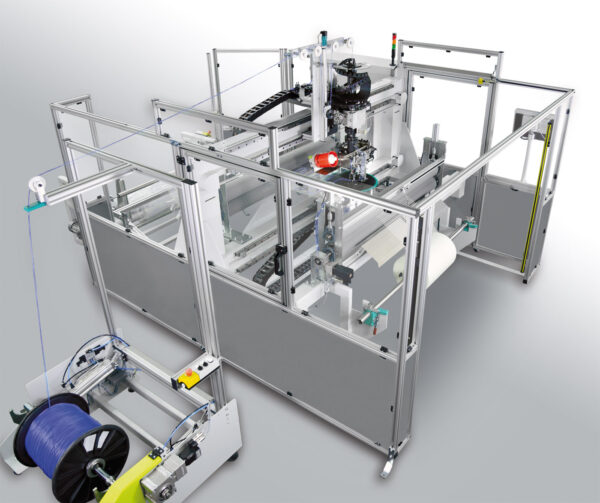

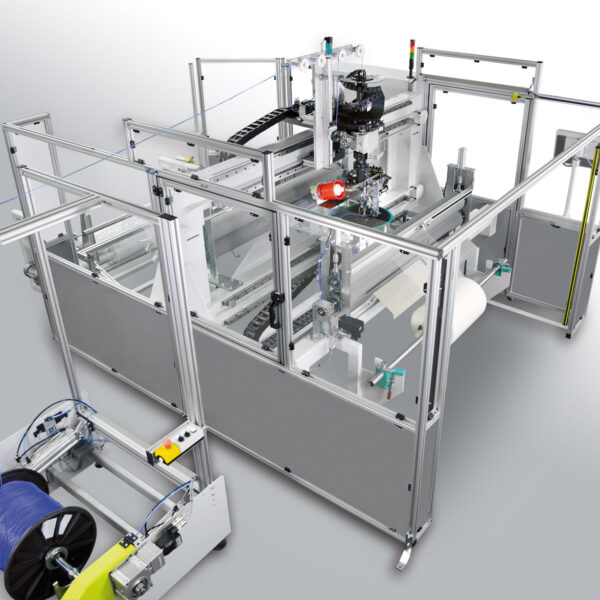

CNC-controlled sewing unit for attaching heating conductors (tubes or cables) on surface heating systems

Features

- Components:

– Unwinding station for cable/tube

– Cable/tube dispenser

– Unwinding station for fabric

– Sewing unit

– Winding station for the finished product - Sophisticated and highly efficient system for this complex operation process

- Fully automatic, autonomous cable/tube laying + sewing (1- or 2-needle chainstitch) with a special laying head. Only the change at the unwinding and winding station is done manually.

- The laying head can be swiveled 360 ° (rotating head) and enables laying even in tight radii

- The unit ensures a laying on flat fabric and mesh fabric (max. width: 1.000 mm)

- The position of the heating surfaces and the length- and crosswise layings are free-programmable

- High-performance PC HMI with large number of service functions and freely definable user level

- For maintenance and error analysis, the HMI can be controlled remotely from a PC, laptop or smart device (using TeamViewer® as standard)

- Planning and implementation of the machine „ready to production“ based on customer requirements.

Specifications

Laying speed: approx. 18 m/min. (amplitude: 960 mm)

Sewing speed: max. 1.800 s. p. m.

Distance between the cables/tubes: from 30 mm free selectable

Max. cable/tube diameter: 8 mm

| Application | Automotive, CNC Sewing, Technical Textiles |

|---|---|

| Technology | CNC Automation |

Reviews

There are no reviews yet.